Hot vulcanised v’s cold bonded lagging

The Elastotec aim is no pulley failures due to inadequate pulley lagging. Compare the difference between cold bonded and hot vulcanised lagging to see that hot vulcanised lagging is A GOOD BUSINESS DECISION.

The Elastotec aim is no pulley failures due to inadequate pulley lagging. Compare the difference between cold bonded and hot vulcanised lagging to see that hot vulcanised lagging is A GOOD BUSINESS DECISION.

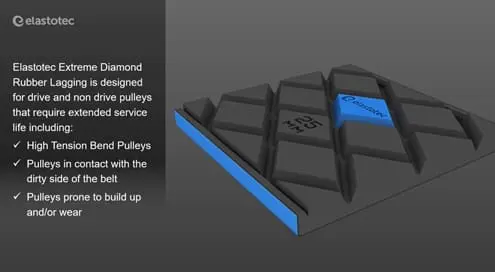

Elastotec extreme diamond rubber lagging is designed for drive and non drive pulleys that require extended service life.

At Elastotec, we engineer lagging solutions that keep conveyors running. Here are some causes of lagging failure.

Hot Vulcanised lagging application involves the chemical cross-linking of five reactive layers during the autoclave curing process. To achieve the desired 100% rubber tear adhesion all five layers must crosslink at the same time. Occasionally conditions can be created in the autoclave that prevent this happening, and result in non-uniform adhesion around the pulley circumference. This bulletin explains how these conditions occur and what needs to be done to eliminate this problem.

Spare pulleys are held so that in the event that an operational pulley requires replacement this can be done quickly and efficiently at the timing dictated by the mine maintenance personnel. The reason for changing a pulley broadly falls into two categories:

Catastrophic lagging failure due to debonding occurred within two weeks of installation and operation of the pulley, resulting in a shutdown of production, and necessitated a replacement of the pulley. Within only two weeks of service, this ceramic lagging was already experiencing loss of the ceramic tiles.

Elastotec Approves New Applicator in Thailand for Hot Vulcanised Ceramic Lagging (HVCL) Early in 2019 Kledkaew Inter Products Co, Ltd. a rubber lining company based