Hot Vulcanised Lagging Application

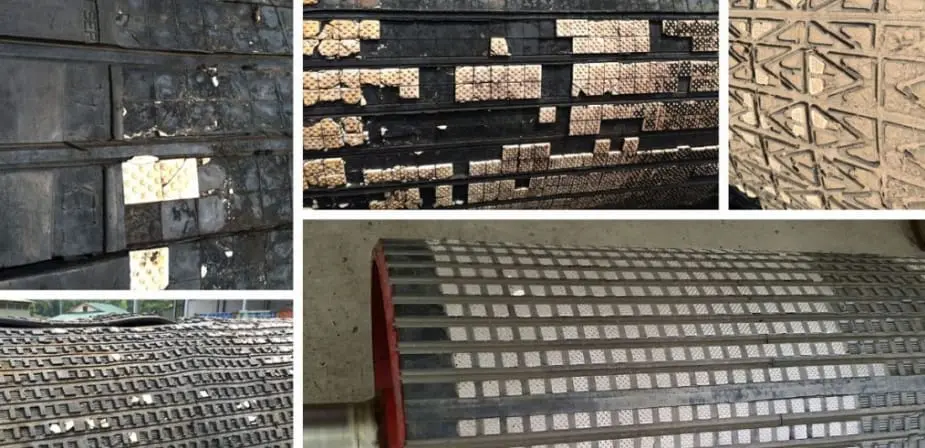

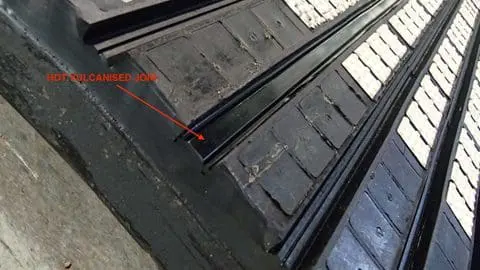

Hot Vulcanised lagging application involves the chemical cross-linking of five reactive layers during the autoclave curing process. To achieve the desired 100% rubber tear adhesion all five layers must crosslink at the same time. Occasionally conditions can be created in the autoclave that prevent this happening, and result in non-uniform adhesion around the pulley circumference. This bulletin explains how these conditions occur and what needs to be done to eliminate this problem.