Improvements in Cold Vulcanised Adhesion of Pulley Lagging

Cold Vulcanised (CV) bonding of pulley lagging has been used for many years primarily due to the convenience of application and the minimal investment required to set up.

It can also be done on site when unexpected lagging problems occur. When done properly CV application can provide an acceptable result for medium and light duty pulley applications however because this method does not provide reliable 100% rubber tear adhesion service life is often compromised.

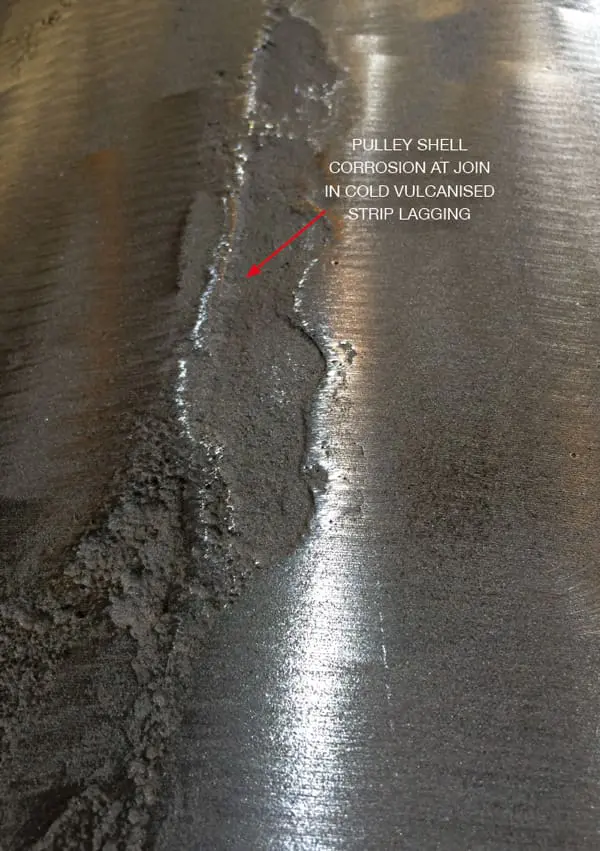

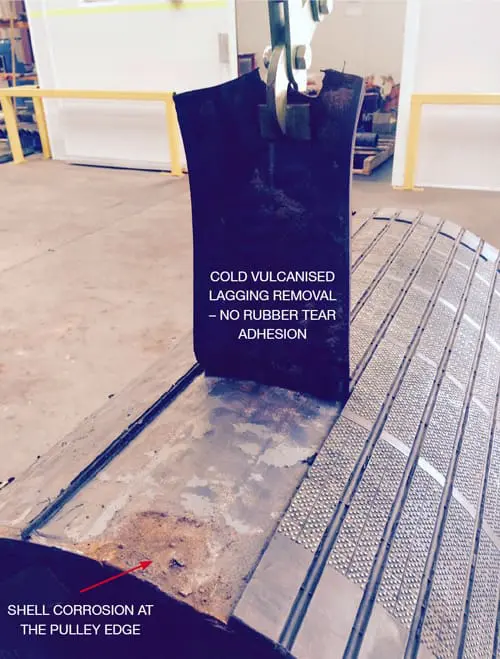

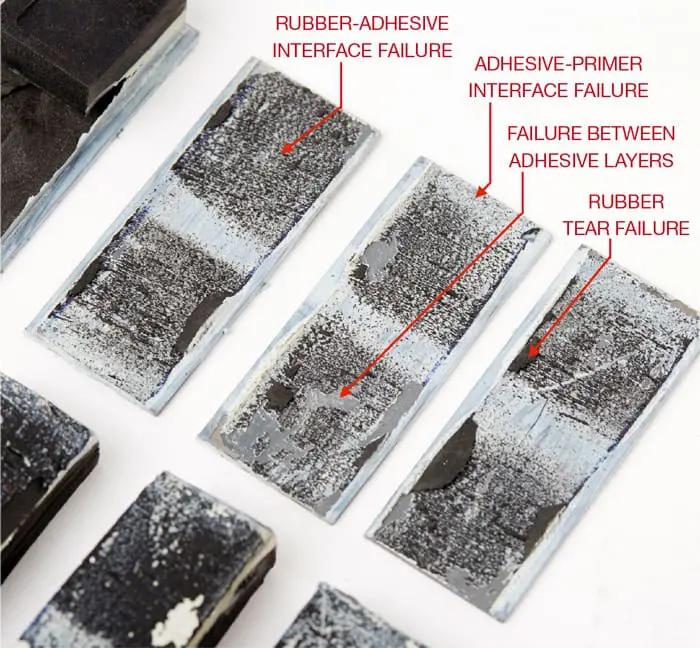

Failure of CV bonding to provide rubber tear adhesion can result in lagging coming away from the pulley and also to corrosion of the pulley shell at the lagging joins with the resultant pitting leading to a de-rating of the pulley service capability due to the reduction in shell thickness. Photo #1 & 2. The cost for these problems in plant down time and pulley refurbishment is always substantial, and in the case of the de-bonding is many times the cost of the original lagging application.

Most people involved in pulley refurbishment and/or lagging replacement know that removal of CV lagging is pretty simple and can be done by applying tension to the end of a lagging strip with a forklift or overhead crane. This usually peels the lagging away from the pulley shell with little or no rubber tear.

Refer to Photo#3. This photo also shows significant pulley shell corrosion adjacent to the pulley edge – this is usually the result of poor adhesion between the lagging and pulley shell and can lead to complete debonding of the lagging and unplanned conveyor down time.

There are many reasons for the failure to obtain rubber tear adhesion with conventional CV bonding systems and lagging including:

- Use of adhesives, primers and lagging that have not been engineered by a single manufacturer to work together

- Lack of detailed OEM application specifications and work methods

- Poorly trained and supervised applicators

- Application in hostile (dirty, wet, humid) conditions

Elastotec has been working to address the first three of these causes of problems with CV bonding systems.

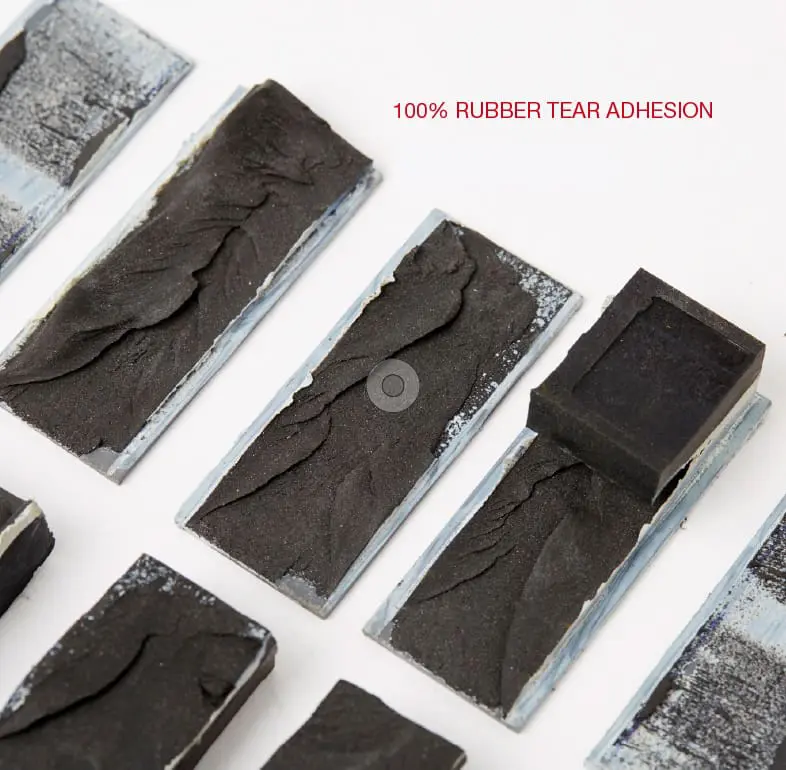

With a focus on “Longer Service Life” of our lagging products Elastotec has been working with an adhesive manufacturer to develop a CV bonding system that provides consistent, reliable 100% rubber tear adhesion. CV bonding is made up of a number of components with the unexpected failure of any component causing substantial cost for mining companies. Our aim was to engineer the CV adhesion system so that any failure always occurs with in the lagging bonding layer i.e. 100% rubber tear. This gives the highest and most consistent adhesion values.

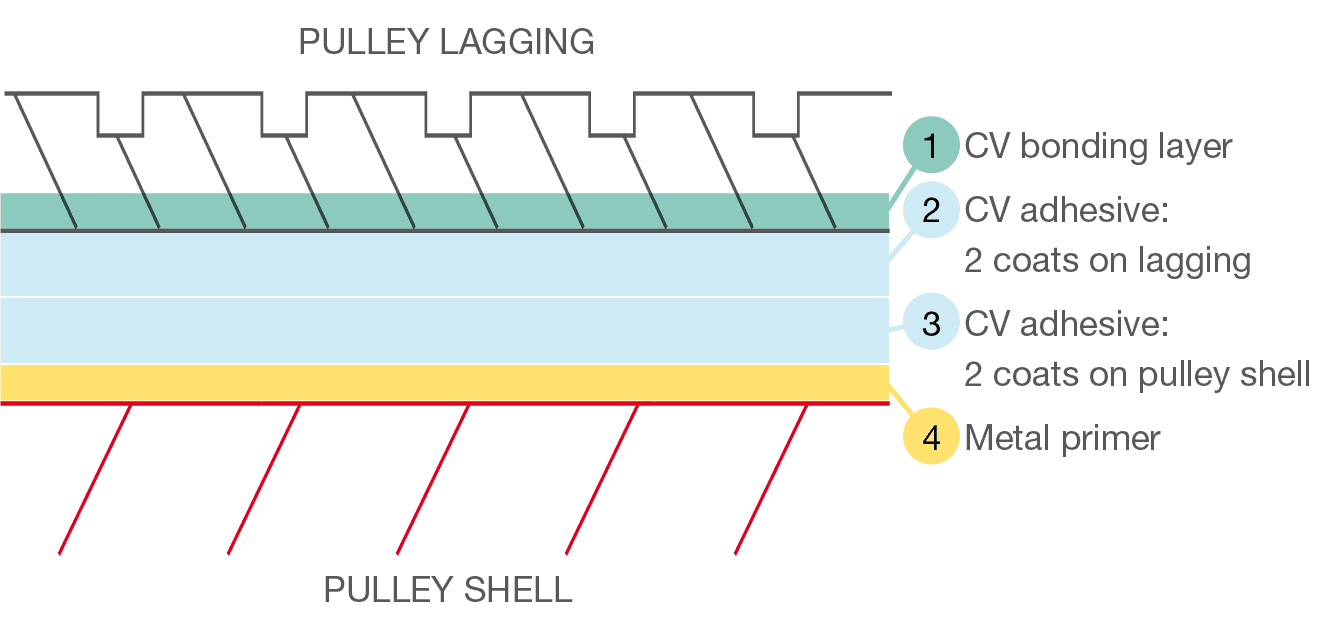

Fig#1 shows the construction of a typical CV bonding system made up of four layers

- Metal Primer

- Layer of CV adhesive applied over the metal primer

- Layer of CV adhesive applied to the lagging

- CN bonding layer as part of the lagging (not all lagging manufacturers have this)

Cold Vulcanised Bonding System

Bond failure can occur between any of these layers and our testing shows that failure at the interface between layers tends to require a much lower force than failure that occurs wholly within the lagging CN bonding layer. From observing many adhesion peel tests the failure at the interface between layers occurs in small localised areas that focus the stress from the applied tension (Refer Photo#4).

Once the interface failure is eliminated and the CN bonding layer becomes the failure point the adhesion results increase substantially and the test readings are very consistent.

The development work to eliminate the three causes of problems with CV bonding systems has resulted in the following improvements:

1) Use of adhesives, primers and lagging engineered by a single manufacturer to work together.

- Metal Primer – commonly used metal primers such as Chemlok 205 are designed for use with hot vulcanised bonding systems where heat activates certain components in the primer. With CV bonding systems the lack of applied heat means that the adhesion to the metal primer is greatly reduced. Elastotec has developed a metal primer that chemically interlocks with components in the adhesive at room temperature forming a much stronger bond than can be obtained with conventional metal priming systems.

- Cold Vulcanising Adhesive (CVA) – the Elastotec CVA has been formulated to contain ingredients that chemically interlock with components in the metal primer and also in the CN bonding layer. When used together this is like a “chemical Velcro” that makes the interface between the various layers stronger than the CN bonding layer.

- CN Bonding Layer – The Elastotec CN bonding layer has been formulated to contain the same components that chemically interlock with the metal primer and CVA with the same “chemical Velcro” adhesion achieved between the other layers. Additionally the properties of this layer have been engineered so that this is the weakest link in the bonding system. Failure due to tearing in the CN bonding layer provides consistent levels of force that are typically 1.5 – 2 times the best results achieved when failure occurs at the interface between one of the system layers.

2) Detailed OEM application specifications and work methods

Elastotec provides detailed application procedures. A number of things have been found “CRITICAL” during the application procedure to obtain high levels of adhesion between the lagging and the pulley shell:

- The application of a uniform first adhesive coating that provides complete coverage of the pulley shell and the lagging surface.

- The elimination of solvent entrapment from both the first and second adhesive coats.

- Ensuring the two adhesive coated surfaces are pressed together at the optimum time so that the adhesive layers can coalesce and become a single layer.

- Obtaining high levels of surface pressure and surface contact between the two surfaces being bonded.

Uniform First Adhesive Coat

It has been observed that the best results are obtained with a thick full coverage first coat on both surfaces (pulley shell and lagging). Elastotec CVA is a light blue colour so that it is easy to identify areas where the coating is too thin because the black surface of the lagging can be seen through the adhesive. The first coat must be uniform enough so that there are no dark areas where the lagging can be seen.

Elimination of Solvent Entrapment

- It is important to ensure that the first coat of adhesive dries completely to ensure there is no chance of solvent entrapment – we recommend a drying time of 60 minutes for the first adhesive coat.

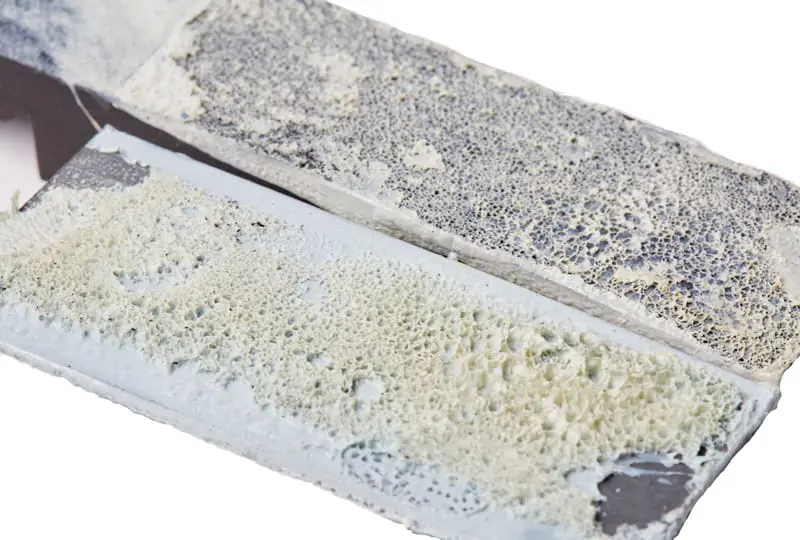

- The function of the second adhesive coat is to make the first coat “tacky” or “sticky” and must be a “light” coat only – a heavy second coat will result in solvent entrapment with poor adhesion results (see Table#1 and Photo#5). Too little drying time can result in solvent entrapment and bond failure in the adhesive layer and too long a drying time results in the adhesive layer losing its “tack” or “ stickiness”. This causes the two adhesive layers to act as separate layers with a resulting greatly reduced adhesion. Maximum adhesion is achieved when the CV adhesive layers combine to form a single layer.

Failure in the adhesive layer due to solvent entrapment

Table #1

| Substrate | Lagging on bonding layer | Primer | Adhesive | 1st coat thickness | 1st coat drying time (min) | 2nd coat thickness | 2nd coat drying time @25°C (min) | Adhesion (N/mm) | Failure mode |

|---|---|---|---|---|---|---|---|---|---|

| Mild Steel | 66511 | 2205 | Elastotec CVLA | Thick | 60 | Thick | 6 | 4.6 | 100% Adhesive layer – solvent entrapment |

| Mild Steel | 66511 | 2205 | Elastotec CVLA | Thick | 60 | Light | 6 | 18.8 | 100% Rubber tear |

Optimum Application Time

The drying time of the second adhesive coat is critical to the final adhesion strength. Elastotec provides detailed recommendations on the required drying times at temperatures from 15 to 35 C for the second coat of our CVA, before the two surfaces are pressed together (see Fig#2 below) – our application method requires that this be timed and recorded for all installations to ensure the best result.

Fig. #2

Surface Pressure/Contact

Adhesion is increased when surface contact and pressure between the two layers being bonded is high. Traditional methods of applying CV lagging use a rubber hammer and rely on the operator to apply the force across consistently over the entire lagging surface. Elastotec recommend the use of pneumatic hammers (Photo#6) for ensuring high levels of surface contact between the lagging and the pulley shell. The pneumatic hammer hits the surface 30 times/second with consistent force. An operator with a manual hammer cannot produce the same level of surface impact or contact coverage.

3) Trained and supervised approved applicators by Elastotec

Elastotec works with approved applicators trained to use the Elastotec Cold Vulcanising application method. This ensures that only skilled operators using OEM materials and application method apply the Elastotec Ceramic Lagging with Elastotec’s Cold vulcanizing adhesion system.

The result is:

- Consistent application to OEM specifications

- Reliable result

- Long life trouble free lagging performance

The combination of three bonding system components developed by Elastotec – Elastotec Metal Primer 2205 – Elastotec CV Adhesive – Elastotec CN Bonding Layer – together with the detailed applications instructions and working with approved and supervised applicators, ensures that Elastotec’s Cold Vulcanising adhesion system provides reliable 100% rubber tear bonds that exceed 18 N/mm. (Refer photo #7)

Prevention of blisters in steam heated autoclaves

This technical bulletin will outline the causes of blister formation and will detail a series of sim

Hot vulcanised v’s cold bonded lagging

The Elastotec aim is no pulley failures due to inadequate pulley lagging. Compare the difference bet

Elastotec adhesion testing

At Elastotec, we engineer lagging solutions that keep conveyors running. Here are some causes of lag