Outdoor ageing performance of Elastotec Ceramic Lagging

Why is ceramic lagging used?

Ceramic lagging is widely used in applications that require increased levels of grip and long service life. The raised dimples on the ceramic tiles in ceramic lagging provide increased grip as they embed into the rubber cover of the belt. Additionally, the hard-wearing properties of the aluminium oxide ceramic provide high levels of abrasion resistance that results in much longer service life than can be achieved with rubber lagging.

Ceramic lagging is often specified for applications where the lagging must last as long as the mechanical components on a pulley i.e. bearings, locking elements etc. Ceramic lagging is a high-performance lagging option with a cost that is substantially higher than traditional rubber lagging.

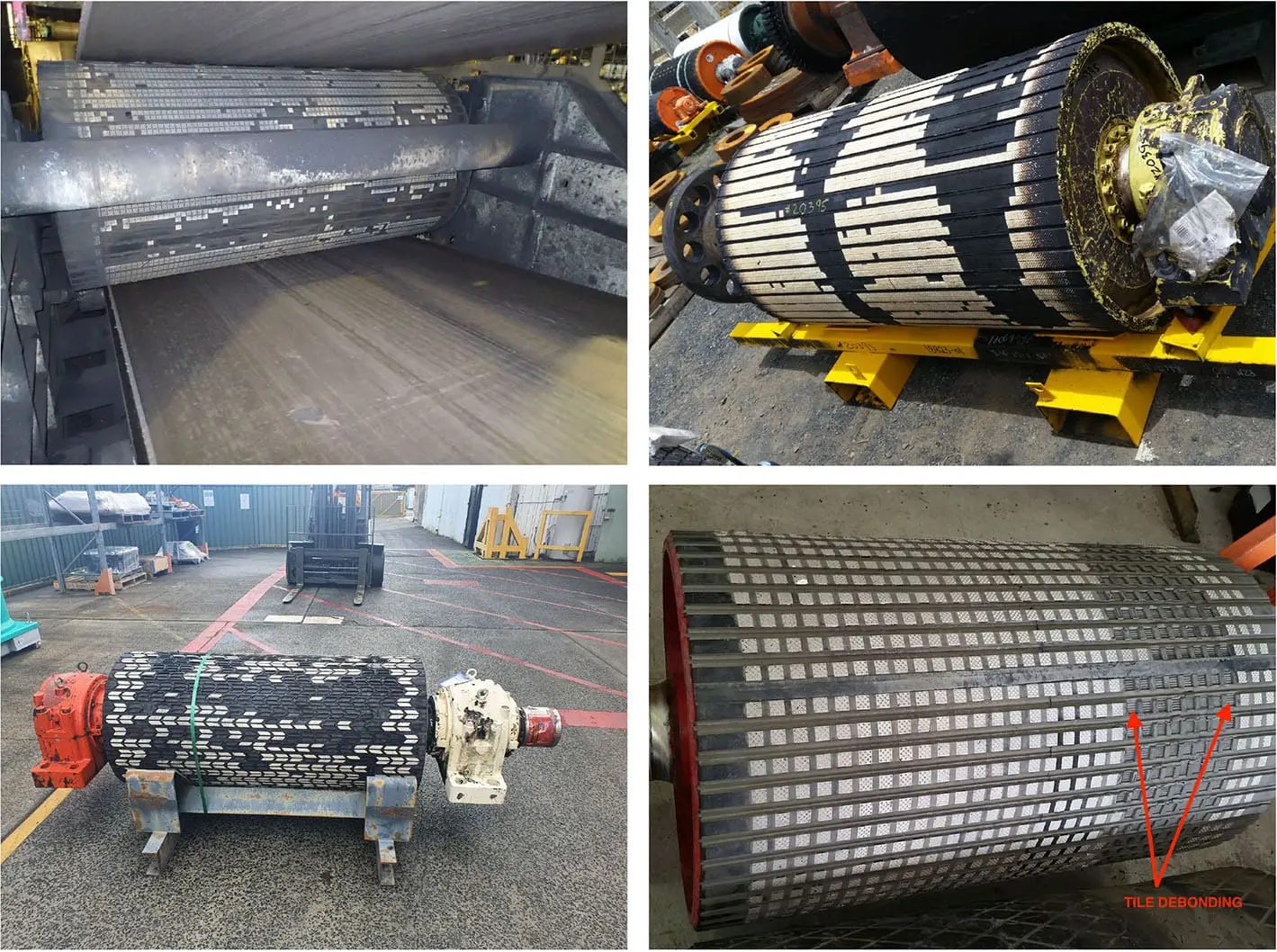

Ceramic lagging failure due to tile loss by debonding

Unfortunately, many manufacturers of ceramic lagging have problems with loss of the ceramic tiles due to debonding. This tile loss is due to many factors including:

• incorrect lagging design

• inadequate product development and testing

• use of low-cost bonding agents

• poor production process control.

Tile loss has a profound effect on the performance of the ceramic lagging and in severe cases can result in an unplanned.

Elimination of ceramic tile loss due to debonding

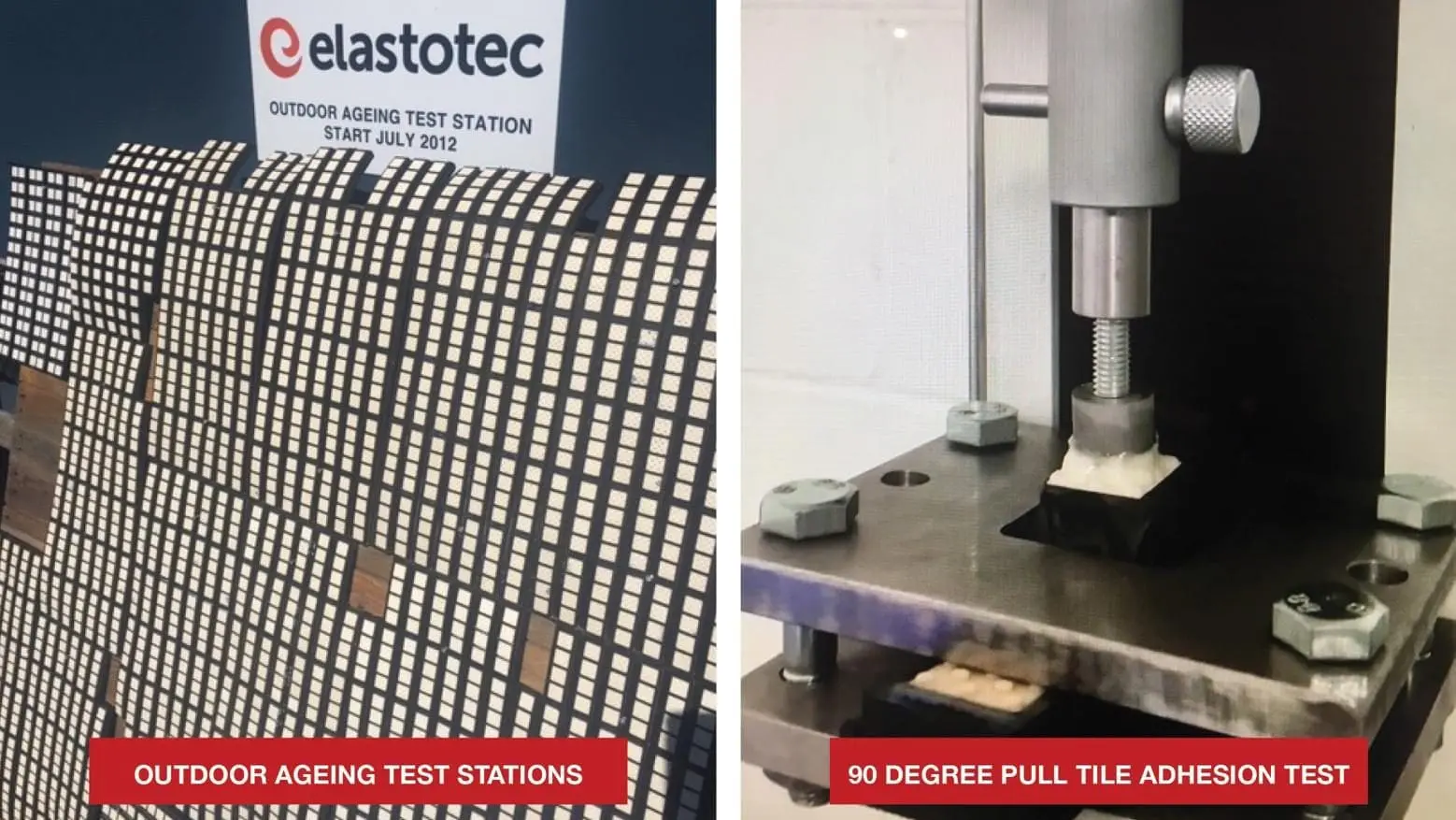

In 2013 Elastotec initated a testing programme to develop a bonding system for aluminium oxide tiles and rubber that did not degrade with age and exposure to water, dirt, UV and ozone. This development tested a dozen different primer coatings and over twenty adhesive systems. Validation of the various bonding systems involved the following separate testing stages:

- Initial adhesion test with flexing at 90 degrees of the tile rubber joint and visually checking for separation at the bond line

- Measure tile pull out force for a 90 degree tension pull (see photo below)

- Check mode of failure for the 90 degree tension pull (this must be 100% RT – Rubber Tear)

- Outdoor ageing with annual checks of the tile adhesion and failure mode.

Elastotec has had this outdoor ageing testing programme in place since 2013 and the test results are shown below. Ceramic lagging samples that have been continuously exposed outdoors since 2013 are tested annually for the adhesion of the ceramic tiles to the rubber backing. The testing method is a 90 degree pull test as shown in the photo below.

90 DEGREE TILE ADHESION TESTING

| Primer | Adhesive | Initial Bond as Manufactured | Bond After Ageing 1 Year 2015 | Bond After Ageing 2 Years 2016 | Bond After Ageing 3 Years 2017 | Bond After Ageing 4 Years 2018 | Bond After Ageing 5 Years 2019 | Bond After Ageing 6 Years 2020 |

|---|---|---|---|---|---|---|---|---|

| A3 | B2 | 31.5 kgf/cm2 | 29.75 kgf/cm2 | 47.75 kgf/cm2 | 52.3 kgf/cm2 | 55.15 kgf/cm2 | 50.8 kgf/cm2 | 48.2 kgf/cm2 |

| A3 | B2 | 100% RT% | 100% RT | 100% RT | 100% RT | 100% RT | 100% RT | 100% RT |

100%RT = 100% Rubber Tear

Based on the test programme and the feedback from customers since 2013, Elastotec provides a three year warranty that no tile loss due to debonding will occur with the Elastotec ceramic lagging.

Large Gold Mine in Australia – increased service life of pulleys with Elastotec/PROK HVCL

One of the largest gold mines in Australia, located in southeast of Perth, produces around 750,000 o

T&T Perú 2023

Thank you to the Peruvian mining sector. Thank you for the space to discuss your challenges. Thank y

Prevention of blisters in steam heated autoclaves

This technical bulletin will outline the causes of blister formation and will detail a series of sim