Description

Application

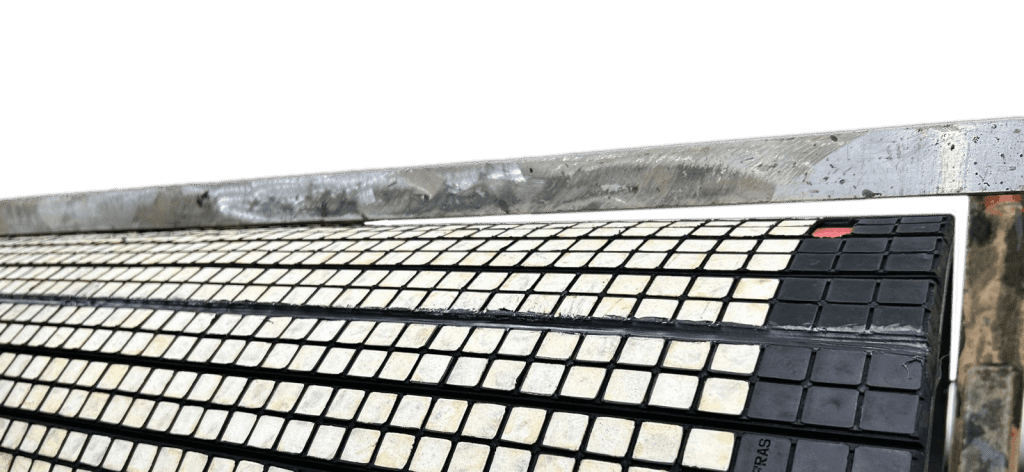

Elastotec Crowned Ceramic Lagging is designed to be applied to conveyor tail, snub, bend or take-up pulleys. It is used for conveyor system applications in the mining, quarrying, mineral and metal processing industries but can be used on any conveyor pulley.

Key features and benefits

- Designed to be applied to flat pulley shells which eliminates the need for machining.

- Improved belt tracking.

- Available in 250mm wide strips that can be made to suit any pulley size and make it easy to install.

- Available in highly abrasion resistant SBR for above ground applications and FRAS for underground and high risk applications.

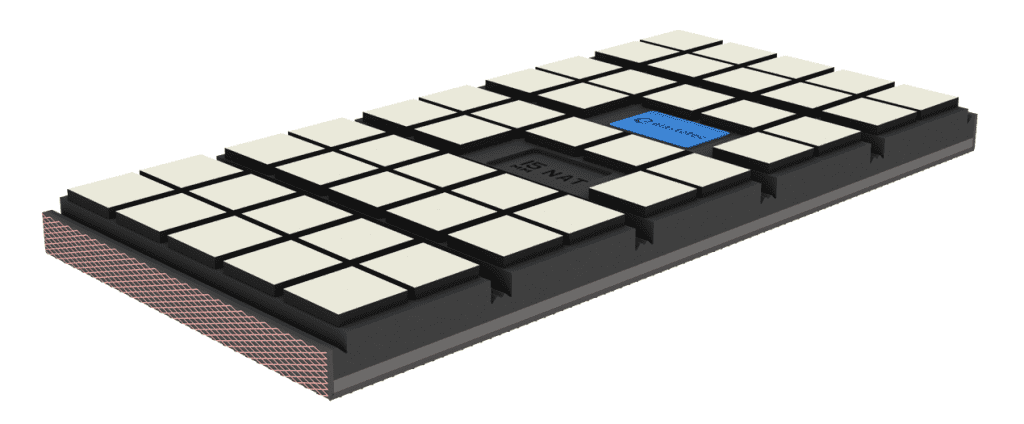

- Coloured logos (Blue for SBR and Red for FRAS).

- High quality rubber formulations designed for good bonding, resistance to degradation by out door exposure, and good abrasion resistance.

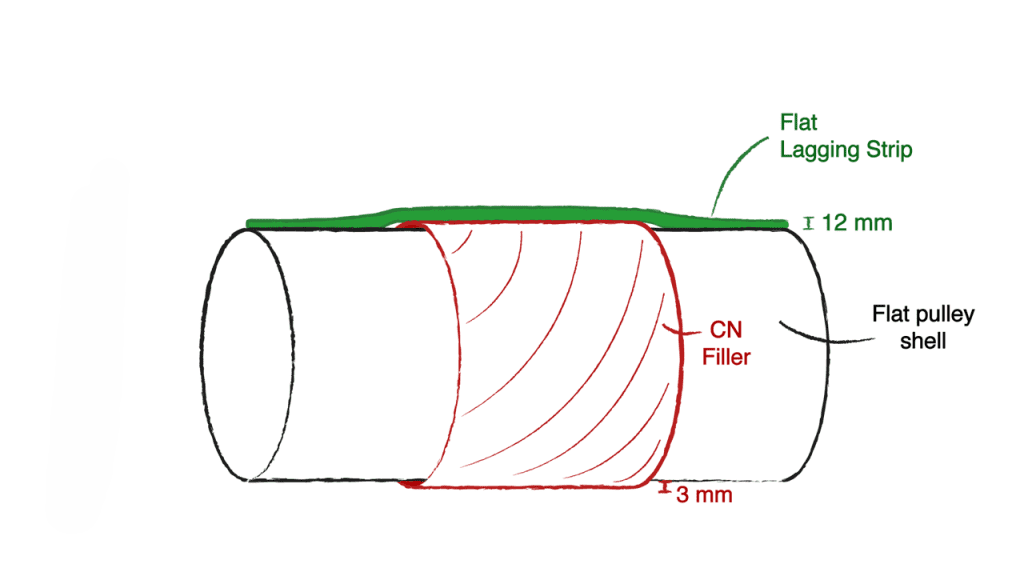

- Buffed CN Bonding layer for increased adhesion for Cold Bonded application.

- Available with uncured bonding layer for Hot Vulcanised application.

- Quicker and easier to apply

- Uniform bonding surface – no gaps

- Uniform crown trasition – kinder to the belt

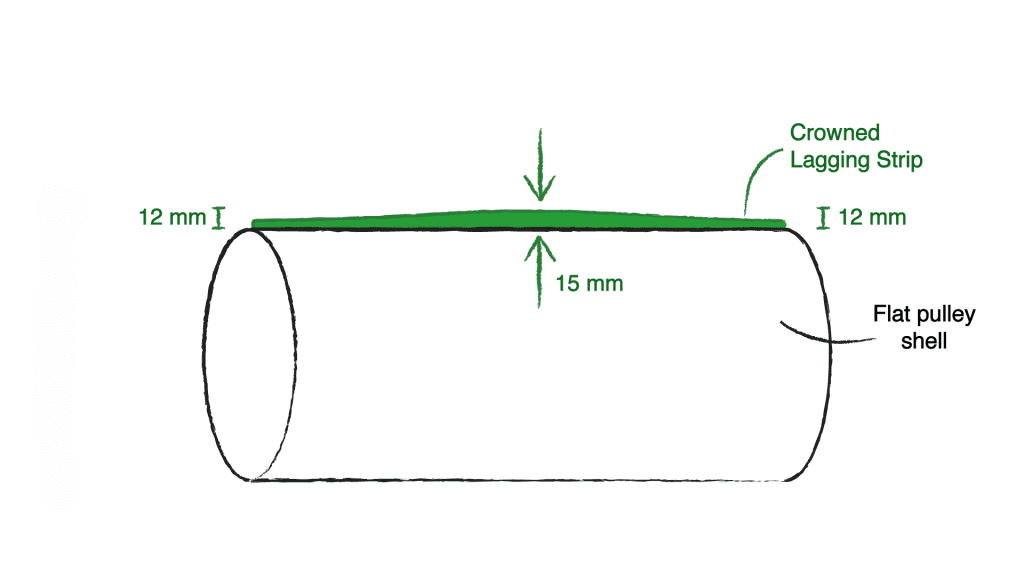

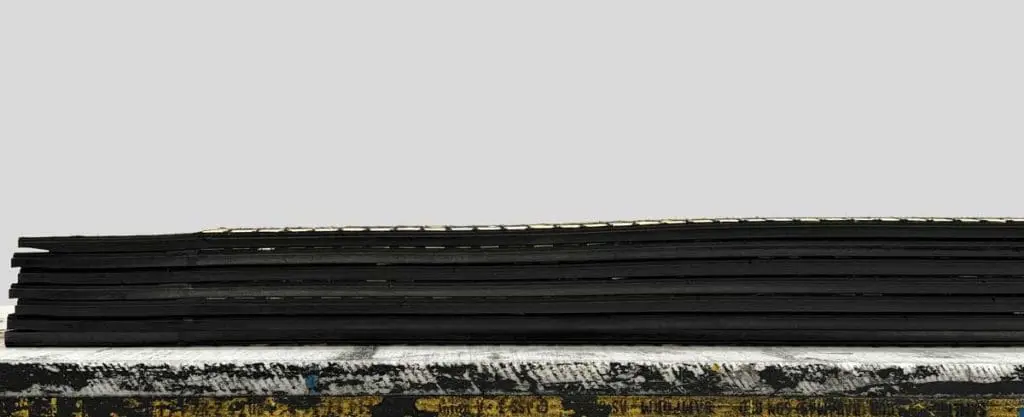

- Standard offering tapers from 15mm through the centre down to 12mm on the ends. (Other thicknesses available)

- Suitable for long term service at temperatures from - 40°C to +70°C.

Design

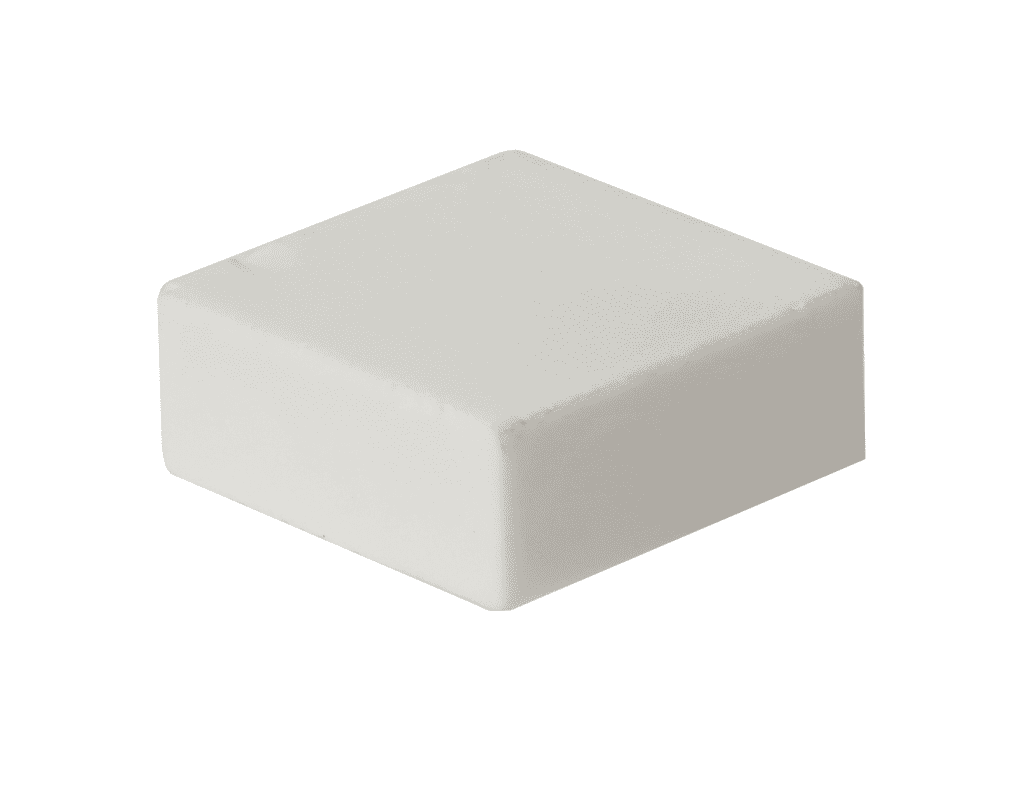

Crowned ceramic lagging strips are designed to ensure outstanding durability while helping to maintain belt alignment without the need for a machined crowned pulley shell.

The central portion of the strips has maximum thickness that gradually decreases towards the ends. Tiles are bonded to rubber on 5 sides to ensure maximum tile to rubber adhesion strength and reduce the risk of breakage.

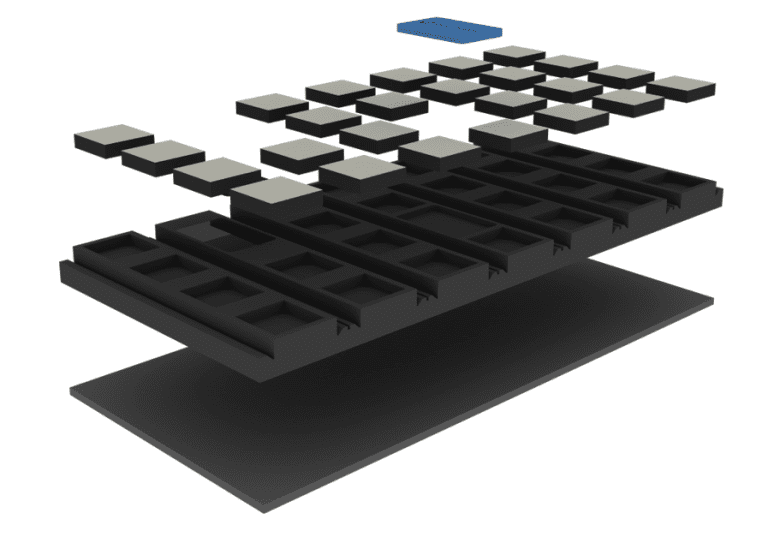

COLD BONDED

Coloured logo

High performance Elastotec ceramic tiles AI203

3 cutting location sipe

CN buffed adhesion layer

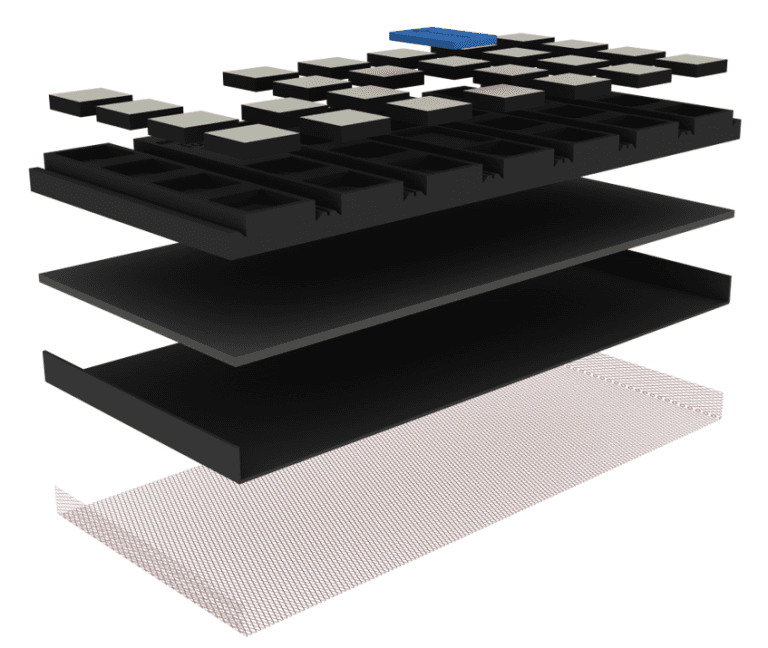

HOT VULCANISED

Edge sipe

Elastotec 100% rubber tear bonding system

Uncured bonding layer

Plastic release liner

Rubber Specifications

CROWNED CERAMIC LAGGING : RUBBER SPECIFICATIONS

Typical values

| NAT | FRAS | |

|---|---|---|

| Polymer | SBR | Blend |

| Tensile strength (MPa) min ISO37 | 18.0 | 16.0 |

| % Elongation min ISO37 | 550% | 500% |

| Hardness (shore A) ISO868 | 65+/-5 | 65+/-5 |

| Abrasion resistance max vol. loss ISO 4649 method A (non-rotating) | 70mm3 | 150mm3 |

| FRAS - MDG3608 and MSHA Standards | N/A | PASS/ACCEPTED |

| Heat ageing (Property change after 70°C 168hs) | Tensile strength +1% Elongation -15% Hardness 5 points | Tensile strength +5% Elongation -1% Hardness 3 points |

| Continuous operating temperature | -40/+70°C | -40/+70°C |

Ceramic Specifications

CROWNED CERAMIC LAGGING : CERAMIC SPECIFICATIONS

Typical values

| Aluminium oxide | 96% |

| Specific gravity g/cm3 | 3.7 |

| Vickers hardness HV (10) | 1000 plus |

| Flexural strength (Mpa) | 300 |

| Compressive strength (Mpa) | 1800 |

| Fracture Toughness (Mpa m1/2) | 3.5 |

Lagging Specifications - Crowned Ceramic 80% Lagging

COLD BONDED – NAT

COLD BONDED - NAT

DIMENSIONS| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH |

|---|---|---|---|---|

| Crowned Ceramic Lagging 15mm Smooth Tiles | ELA-CWDRC80-N-15P | 250mm-252mm | 15mm middle 12mm ends | fit to pulley size |

COLD BONDED – FRAS

COLD BONDED - FRAS

DIMENSIONS| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH |

|---|---|---|---|---|

| Crowned Ceramic Lagging 15mm Smooth Tiles | ELA-CWDRC80-N-15P | 250mm-252mm | 15mm middle 12mm ends | fit to pulley size |

HOT VULCANISED – NAT

HOT VULCANISED - NAT

DIMENSIONS| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH |

|---|---|---|---|---|

| Crowned Ceramic Lagging 15mm Smooth Tiles | ELA-CWDRC80-N-15PV | 251mm-255mm | 15mm middle 12mm ends | fit to pulley size |

HOT VULCANISED – FRAS

HOT VULCANISED - FRAS

DIMENSIONS| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH |

|---|---|---|---|---|

| Crowned Ceramic Lagging 15mm Smooth Tiles | ELA-CWDRC80-F-15PV | 251mm-255mm | 15mm middle 12mm ends | fit to pulley size |

Example:

Strip: Crowned 80% Ceramic Lagging, smooth tiles, for pulley face width 1900mm natural rubber, hot vulcanised: ELA-CWDRC80-DIA-F-15P-1900