Description

Application

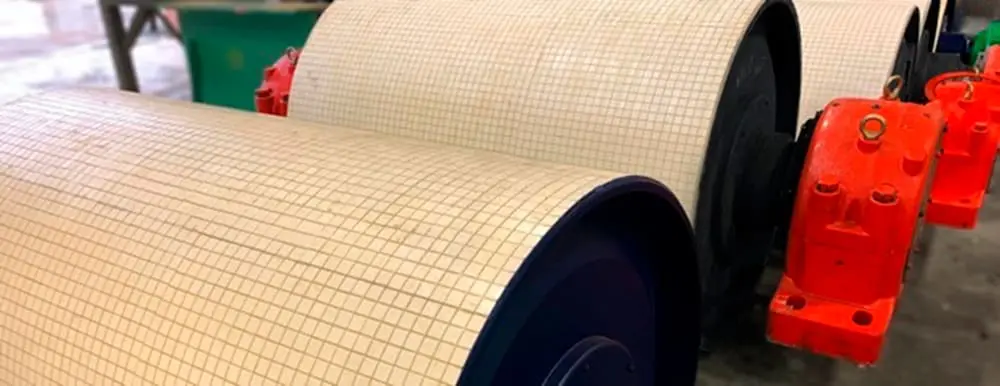

Elastotec Direct Bond Ceramic Lagging is designed for use on drive and non-drive conveyor pulleys. This lagging provides a maintenance free wear resistant surface that will provide increased traction for drive pulleys and a smooth surface for bend and tail pulleys.

Key features and benefits

- High friction coefficient on drive pulleys.

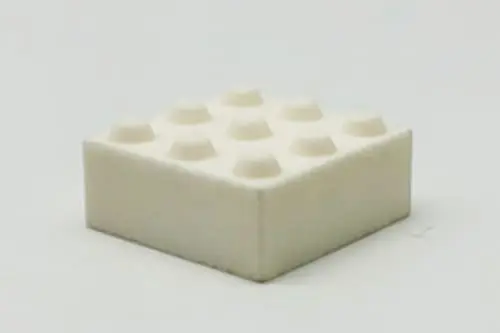

- Grouted tiles decrease the risk of ingress and corrosion and have longer service life and superior bonding strength.

- Maintenance-free, wear-resistant cover applied to pulley shells that contribute to reduced downtime and lower operating costs by improving traction in drive pulleys and providing a hard-wearing surface on non-drive pulleys.

- Drive Pulleys have dewatering grooves that dissipate water and can be hosed down without losing traction. And studs with rounded edges that present a less severe interface with the belt bottom cover.

- Smooth ceramic on Non-Drive Pulleys provides a low maintenance surface with proven long service life under a variety of conditions.

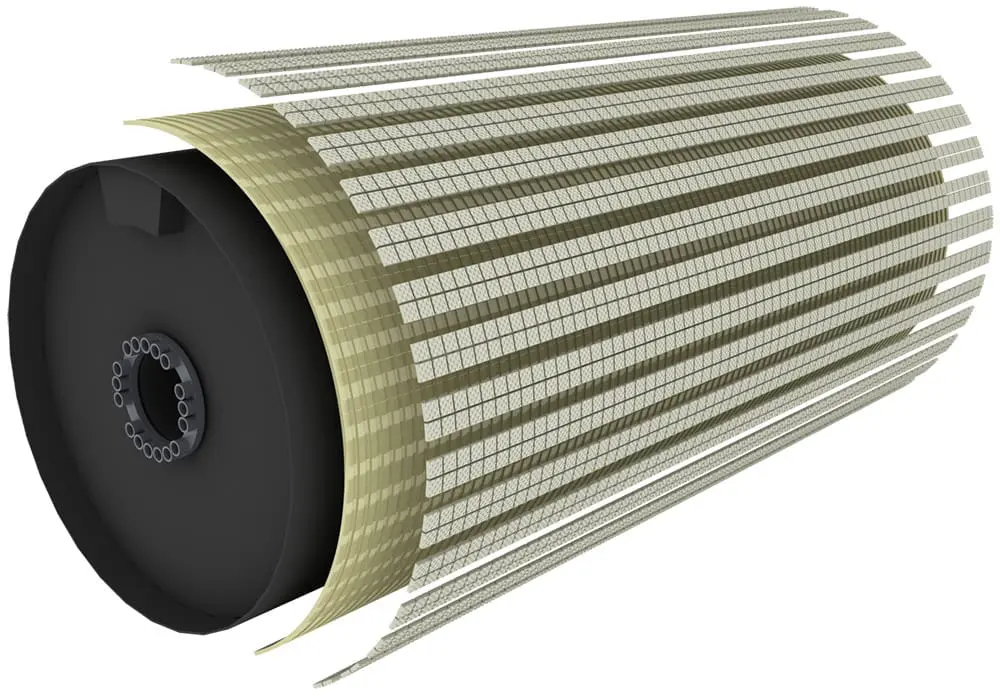

- Innovative application method reduces application time and ensures tile alignment.

Important considerations for Direct Bond Ceramic Lagging

Direct Bond Ceramic Lagging is selected as a lagging solution due to its high adhesion strength of ceramic tiles to the pulley shell through the epoxy adhesive (>20MPa). In the right application, the direct bond provides a maintenance-free surface.

Direct Bond behaves differently to rubber-based laggings and needs to be carefully assessed before being selected. Direct bond is a rigid pulley lagging and does not have the flexibility that rubber-based laggings have.

Aspects to consider when selecting direct bond lagging:

- Maximum allowable pulley shell flexing in centre 0.5mm. Cyclic flexing of the pulley shell can cause tile debonding.

- Rubber-based laggings expand and contract when moving from the belt contact area to the non-belt contact area. This cyclic exercise helps prevent the build-up of material. Direct Bond Lagging is rigid and does not have the ability to expand and contract.

- Lagging and belt surfaces in contact are affected by cyclic stresses. On a drive pulley, belt tension goes from high T1 at the entry to lower T2 at the exit. The belt tries to retract from exit to entry. The belt retraction can cause localised slippage if lagging is not flexible enough to keep engagement. Direct Bond Ceramic Lagging needs to be evaluated for localised slippage before installation.

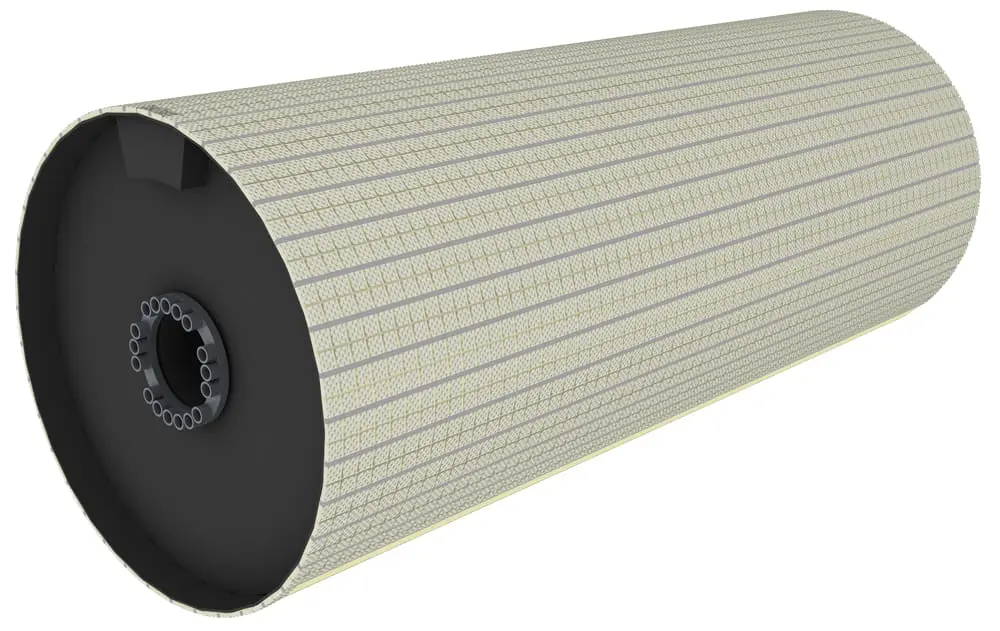

Design

Elastotec’s unique Direct Bond Ceramic Lagging system was developed to provide a lagging for use on both drive and non-drive pulleys that provide exceptional levels of service life.

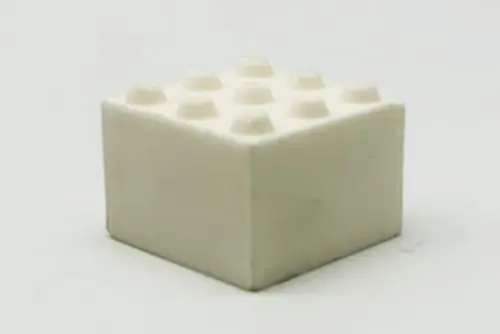

HDPE infill spacer

Direct bond adhesive

Ceramic proven tile design

High performance Elastotec ceramic tiles

Ceramic specifications

Direct bond Ceramic Lagging can be supplied in different ceramic tile thicknesses 6mm, 10.5mm and 13.5mm (tile body thickness) and in dimple and smooth surfaces.

6mm Ceramic Tile

| 6mm Ceramic Tile Property | Drive | Non-drive |

|---|---|---|

| Aluminium oxide | 95% | 92% |

| Specific gravity g/cm3 | 3.7 | 3.6 |

| Vickers hardness (HV10) | 1200 | 1000 |

| Flexural strength (Mpa) | 300 | 270 |

10.5mm Ceramic Tile

| 10.5mm Ceramic Tile Property | Drive & Non-Drive |

|---|---|

| Aluminium oxide | 95% |

| Specific gravity g/cm3 | 3.7 |

| Vickers hardness (HV10) | 1200 |

| Flexural strength (Mpa) | 300 |

13.5mm Ceramic Tile

| 13.5mm Ceramic Tile Property | Drive & Non-Drive |

|---|---|

| Aluminium oxide | 95% |

| Specific gravity g/cm3 | 3.7 |

| Vickers hardness (HV10) | 1200 |

| Flexural strength (Mpa) | 300 |

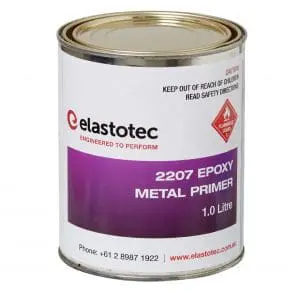

Primer and adhesive specifications

Elastotec Direct Bond Ceramic Lagging had an epoxy-based adhesion system. High-strength bonding system to provide adhesion of the ceramic tiles to the pulley shell >20MPa. Metal primer for application to the steel pulley shell immediately after sandblasting to prevent oxidation and a 2-part epoxy adhesive that can be mixed manually or through a pneumatic mixing gun to reduce waste.

The Elastotec Direct Bond Adhesive has been formulated to combine excellent adhesion to the steel pulley shell and the aluminium oxide tiles with robust processing characteristics. This adhesive has proven performance for outdoor service exposed to UV, water, dust, dirt, etc.

DIRECT BOND METAL PRIMER

DIRECT BOND ADHESIVE

Operating temperatures

-20°C to +50°C

DIRECT BOND ADHESIVE HIGH-TEMPERATURE

Operating temperatures

-20°C to +110°C

Typical adhesion values

| TEMP°C | RECOMMENDED ADHESIVE | VALUE |

|---|---|---|

| 25°C - 50°C | Elastotec Direct Bond Adhesive | 25MPa |

| 70°C | Elastotec Direct Bond Adhesive High Temperature | 20MPa |

| 110°C | Elastotec Direct Bond Adhesive High Temperature | 13MPa |

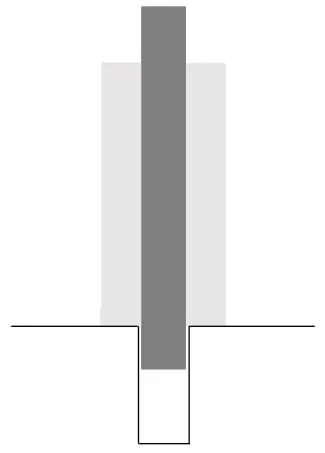

Tile edge flat on surface and perpendicular to applied load.

Applied load

Two 100x25mm tiles (one either side of 12mm steel plate)

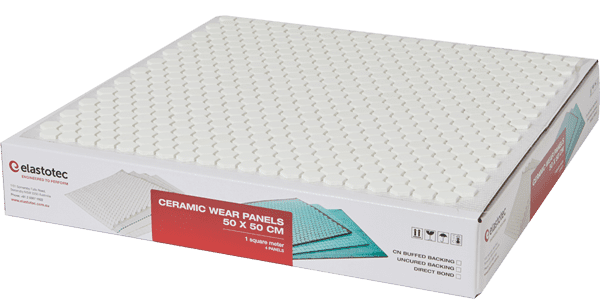

Lagging specifications – Direct Bond Ceramic Lagging

DIRECT BOND CERAMIC LAGGING - DRIVE 6mm

Dimensions: Pads 500x500mm Tiles 20x20x6mm. With spacers every second row of tile.

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Drive 6mm Tiles | ELA-DBCL-D-500-500-06 | 20x20x6mm +1mm dimples top +1mm dimples bottom | 1.5mm | 460 | 4 | 500mm | 500mm | 1 | 21Kg |

DIRECT BOND CERAMIC LAGGING EXTREME - DRIVE 10.5mm

Dimensions: Pads 500mmx500mm Tiles 20x20x10.5mm. With spacers every second row of tile.

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Drive 10.5mm Tiles | ELA-DBCL-D-500-500-10.5 | 20x20x10.5mm +1.5mm dimple | 2.5mm | 440 | 4 | 500mm | 500mm | 1 | 32Kg |

DIRECT BOND CERAMIC LAGGING EXTREME - DRIVE 13.5mm

Dimensions: Pads 500mmx500mm Tiles 20x20x13.5mm. With spacers every fourth row of tile.

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Drive 13.5mm Tiles | ELA-DBCL-D-500-500-13.5 | 20x20x13.5mm +1.5mm dimple | 2.5mm | 440 | 4 | 500mm | 500mm | 1 | 40Kg |

DIRECT BOND CERAMIC LAGGING - NON-DRIVE 6mm

Dimensions: Non-drive pads 500x500mm Tiles 20x20x6mm

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Non-drive 6mm Tiles | ELA-DBCL-ND-500-500-06 | 20x20x6mm body | 1.5mm | 23x23 Total 529 | 4 | 500mm | 500mm | 1 | 21Kg |

DIRECT BOND CERAMIC LAGGING EXTREME - NON-DRIVE 10.5mm

Dimensions: Pads 500mmx500mm Tiles 20x20x10.5mm.

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Non Drive 10.5mm Tiles | ELA-DBCL-ND-500-500-10.5 | 20x20x10.5mm +1.5mm dimples on bottom | 2.5mm | 440 | 4 | 500mm | 500mm | 1 | 32Kg |

DIRECT BOND CERAMIC LAGGING EXTREME - NON-DRIVE 13.5mm

Dimensions: Pads 500mmx500mm Tiles 20x20x13.5mm.

| PRODUCT | CODE | TILE SIZE | TILE SEPARATION | TILES/PAD | PADS/CARTON | PAD WIDTH | PAD LENGTH | SQM/CARTON | WEIGHT/sqm |

|---|---|---|---|---|---|---|---|---|---|

| Direct Bond Non Drive 13.5mm Tiles | ELA-DBCL-ND-500-500-13.5 | 20x20x 13.5mm +1.5mm dimple on bottom | 2.5mm | 440 | 4 | 500mm | 500mm | 1 | 40Kg |

Storage recommendations:

- Stock usage based on a first-in first-out method (FIFO).

- The storage room for lagging must be cool, dry and dust-free.

- Avoid storage places near sources of ozone generating equipment.

- Do not store outside.

- Avoid storage in direct sunlight and strong artificial light as UV light can damage the products and may lead to a premature ageing.

- Under no circumstances should fuels, lubricants, acids, disinfectants, solvents or other chemicals be stored in the same storage area.

- Keep the storage place clean. Protect the material from dust, water etc. with suitable coverings.

- Allow 24 hours before use when lagging is removed from cold storage.

Shelf life

DIRECT BOND LAGGING AND WEAR PANELS

- Stored <25°C

ADHESIVES AND PRIMERS

- Store in flammable goods cabinet

- Stored <25°C

- Shelf life:

- Primers 2 years

- Cold bonding adhesive 2 years

- Hot vulcanising adhesive 12 months

- Direct bond adhesive 2 years

Products stored under the above conditions for longer periods of time than recommended need to be re-tested for adhesion before being used. If any doubts on storage recommendations, contact Elastotec.