Description

Application

Elastotec Extreme Rubber Lagging is designed for the following conditions:

- Uneven belt top cover profile due to wear.

- Presence of carry back that can cause build up and resultant belt damage

- High power, high tension conveyor belts (Up to 3,000 kN belt tensions).

- Extreme temperatures from -40°C to +60°C.

- Extended outdoor operational service.

- To protect the belt from high localised shear forces that result from belt top cover wear.

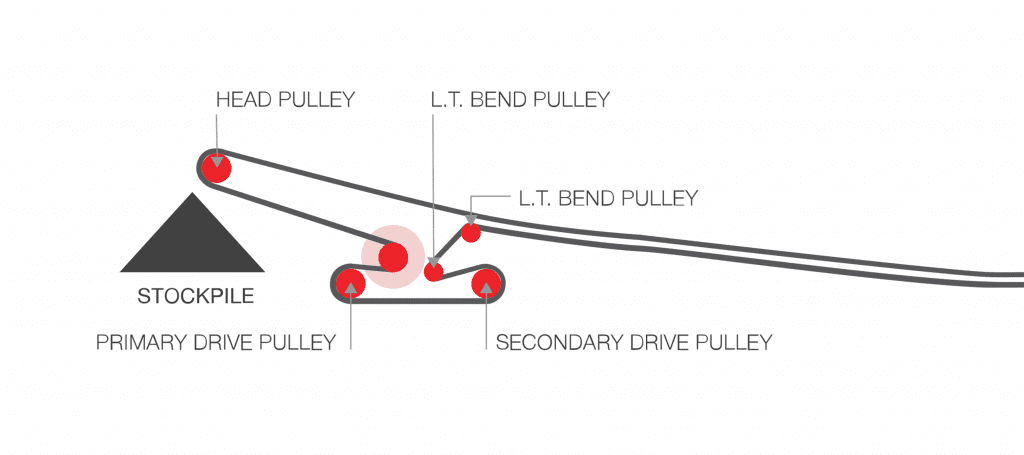

Elastotec Extreme Rubber Lagging is designed for use in the following demanding applications:

- Non drive pulleys with requirement to extend service life.

- Large non drive pulleys on high power belt conveyors that are in contact with the dirty side of the belt. This includes gearless drive conveyors with power ratings of up to 6MW.

- Pulleys where high levels of carry back are present.

- Pulleys in locations that are difficult to access and where pulley change out is difficult.

- Critical locations where unplanned conveyor downtime due to lagging failure must be eliminated.

- Conveyors that operate across a wide temperature range.

- Pulleys subjected to high localised shear forces due to uneven belt profile caused by wear of the belt top cover.

Key features and benefits

- Soft (60A Duro), flexible abrasion resistant rubber to absorb high localised shear forces and protect the belt.

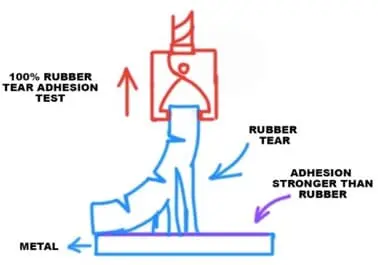

- Advanced bonding system provides 100% rubber tear adhesion to handle localised shear forces, extremes of temperature and wet operating conditions. This bonding system eliminates the chance of the lagging debonding from the pulley shell and the chance of separation of the lagging at the joins between strips.

- High performance abrasion resistant synthetic elastomer with typical abrasion of 29 mm3 volume loss (DIN53516 Method A Non rotating).

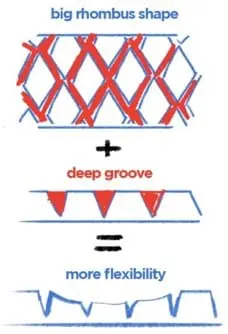

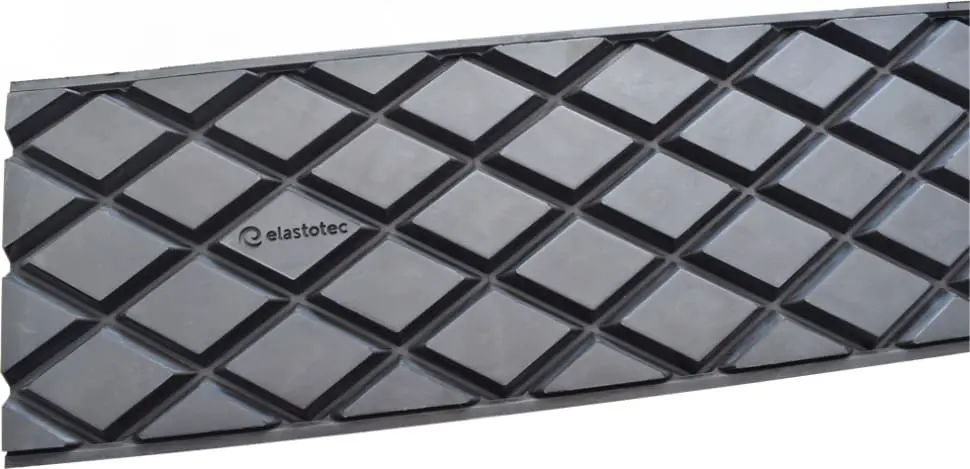

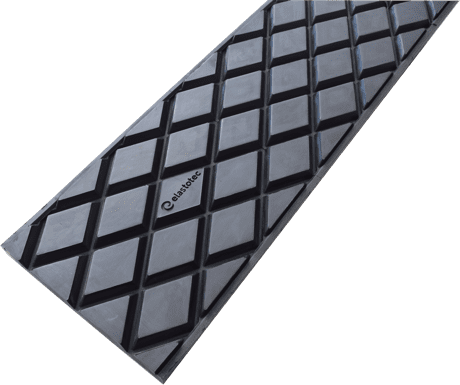

- Diamond pattern with large diamonds and deep grooves to provide flexibility to handle localised shear stresses and protect the conveyor belt.

- Reusable filled silicone infill strip used during lagging application curing process to ensure even pressure on surface.

Lagging requirements for high tension bend pulleys

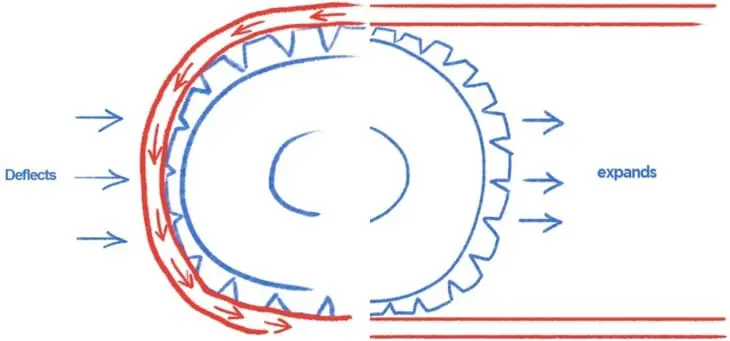

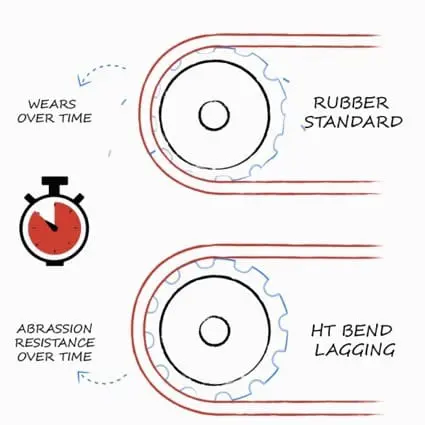

- Soft (60 Shore A), flexible and abrasion resistant to absorb high localised shear forces.

- Abrasion resistant – to resist wear and provide long service life.

- Strong bond to steel – to prevent debonding from the pulley shell.

- Flexible – to allow the lagging to deform and compensate for high localised shear forces and be resistant to build up of carryback.

Design

This new lagging from Elastotec utilises advanced elastomer technology that has been developed to provide a level of operational performance far in excess to any lagging that is currently available.

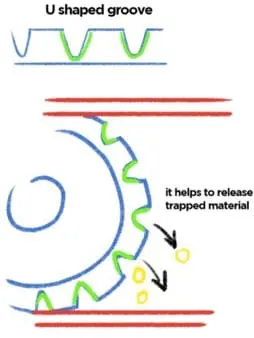

Diamonds work independently to each other

to absorb high localised shear stresses created

by uneven belt surface (dirty side).

U shaped deep grooves for increased

flexibility and improved carry back

material release.

Design and compound engineered

to absorb localised shear stresses produced

by uneven distribution of tension

Plastic release liner

Compound abrasion resistance

more than x2 standard rubber

compounds for extra service life.

25mm thick for extra flexibility.

Uncured bonding layer

for hot vulcanising

Rubber Specifications

| Base polymer | Proprietary blend |

|---|---|

| Hardness range ASTM D2240 | 60 |

| Tensile strength ASTM D412 | 17 Mpa |

| Elongation at break ASTM D412 | 550% |

| Abrasion loss (volume loss) DIN 53516 – non-rotating – method A | 29mm3 |

ADHESION REQUIREMENTS

| Adhesion to steel @ +25 C | 20N/mm & 100% | Rubber tear | ASTM D429 method B 90 deg peel test |

| Adhesion to steel @ +40 C | 20N/mm & 100% | Rubber tear | ASTM D429 method B 90 deg peel test |

| Adhesion to steel @ +50 C | 10N/mm & 100% | Rubber tear | ASTM D429 method B 90 deg peel test |

LAGGING SPECIFICATIONS – EXTREME RUBBER LAGGING

Lagging manufactured using an extremely abrasion resistant top rubber layer 60 duro hardness. Design with large diamonds and deep U shaped grooves for extra flexibility to absorb concentrated shear stresses.

EXTREME RUBBER LAGGING

DIMENSIONS

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| Extreme Rubber Lagging 25mm | ELA-RL-HTB-HAR60-25V | 249mm-251mm | 25mm-26.2mm | Custom | 7.00kg/m |

| Extreme Rubber Lagging 16mm | ELA-RL-HTB-HAR60-16V | 249mm-251mm | 16mm-17.2mm | Custom | Custom |

Product code for different lengths: Add 5 digit number indicating length in mm.

Example: 25mm 2200mm strip product code: ELA-RL-HTB-HAR60-25V-02200

Always allow 100mm extra length over the pulley face width to have 50mm at each end of overhang.

Thickness variation (all strips/pulley) +/-0.5mm

Lagging only recommended for pulleys with diameters over 600mm.

How to store lagging:

- Stock usage based on a first-in first-out method (FIFO).

- The storage room for lagging must be cool, dry and dust-free.

- Avoid storage places near sources of ozone generating equipment.

- Do not store outside.

- Avoid storage in direct sunlight and strong artificial light as UV light can damage the products and may lead to a premature ageing.

- Under no circumstances should fuels, lubricants, acids, disinfectants, solvents or other chemicals be stored in the same storage area.

- Keep the storage place clean. Protect the material from dust, water etc. with suitable coverings.

- Allow 24 hours before use when lagging is removed from cold storage.

Shelf life

HOT VULCANISED LAGGING AND WEAR PANELS

- <7°C and away from UV and ozone generating equipment 12 months. Products stored for longer than 6 months will need to be re-tested for adhesion before being used, and the recommended shelf life is 12 months.

ADHESIVES AND PRIMERS

- Store in flammable goods cabinet

- Stored <25°C

- Shelf life:

- Primers 2 years

- Cold bonding adhesive 2 years

- Hot vulcanising adhesive 12 months

- Direct bond adhesive 2 years

Products stored under the above conditions for longer periods of time than recommended need to be re-tested for adhesion before being used. If any doubts on storage recommendations, contact Elastotec.