Description

Application

Key features and benefits

- Up to 96% Aluminium oxide tile material provide extreme wear resistance.

- Rubber compound blended with CN polymers provide outstanding adhesion to ceramic tiles, rubber and metal.

- Buffed CN bonding layer and buffed edges for optimum cold vulcanised adhesion to the pulley.

- Available in NAT/SBR for above ground applications and FRAS/MSHA certified for underground and high risk applications.

- Ceramic tiles bonded to rubber on 5 sides to resist tile cracking and debonding.

- Supplied as custom length strips with rubber ends to suit any pulley size.

- Dimpled tiles for increased grip on drive pulleys, and smooth tiles to protect non drive pulleys from damaging the belt cover.

- Can be applied by cold bond or hot vulcanised.

- Cutting sipes allow adjustment of strip width to suit any pulley diameter.

- Available in a range of thicknesses (12,15, 20 and 25mm).

- Suitable for long term service at temperatures from - 40°C to +70°C.

- Double Row tile pattern designed to deliver optimal performance and reduce lagging fatigue.

Design

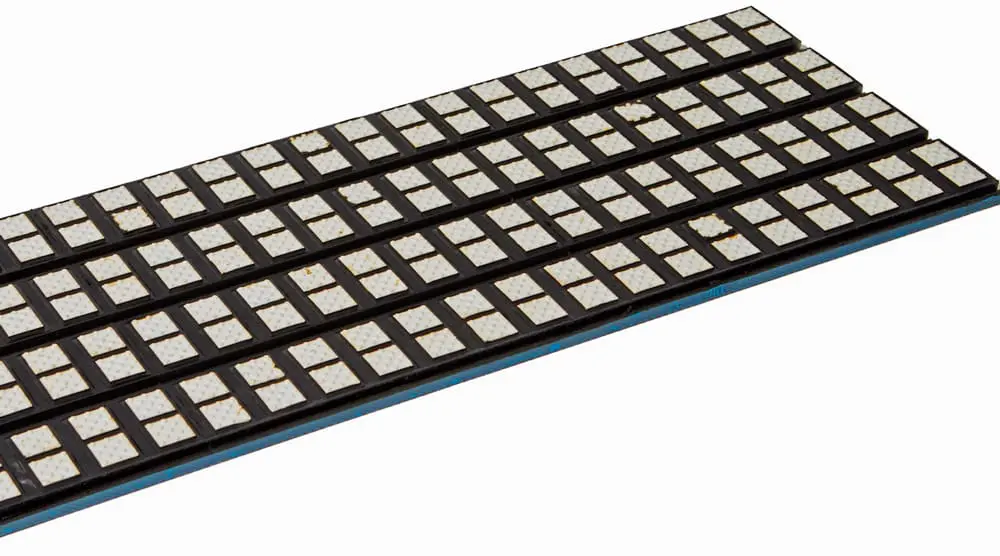

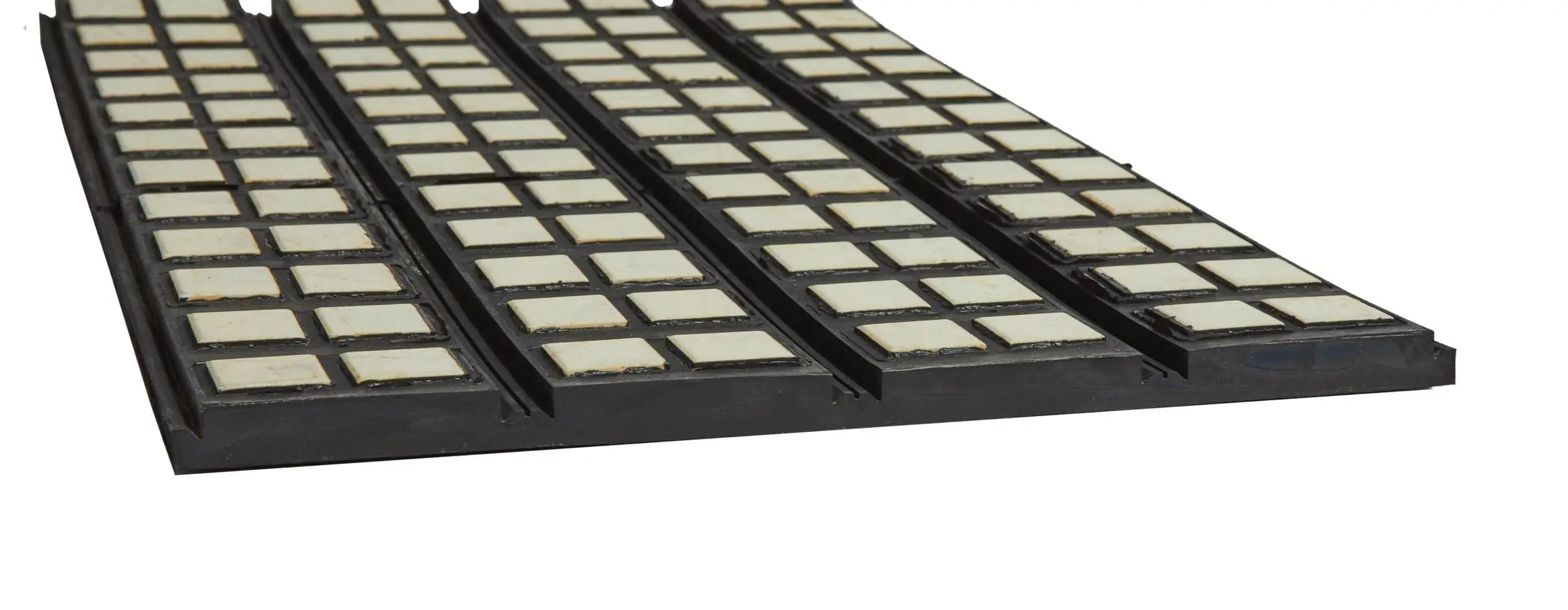

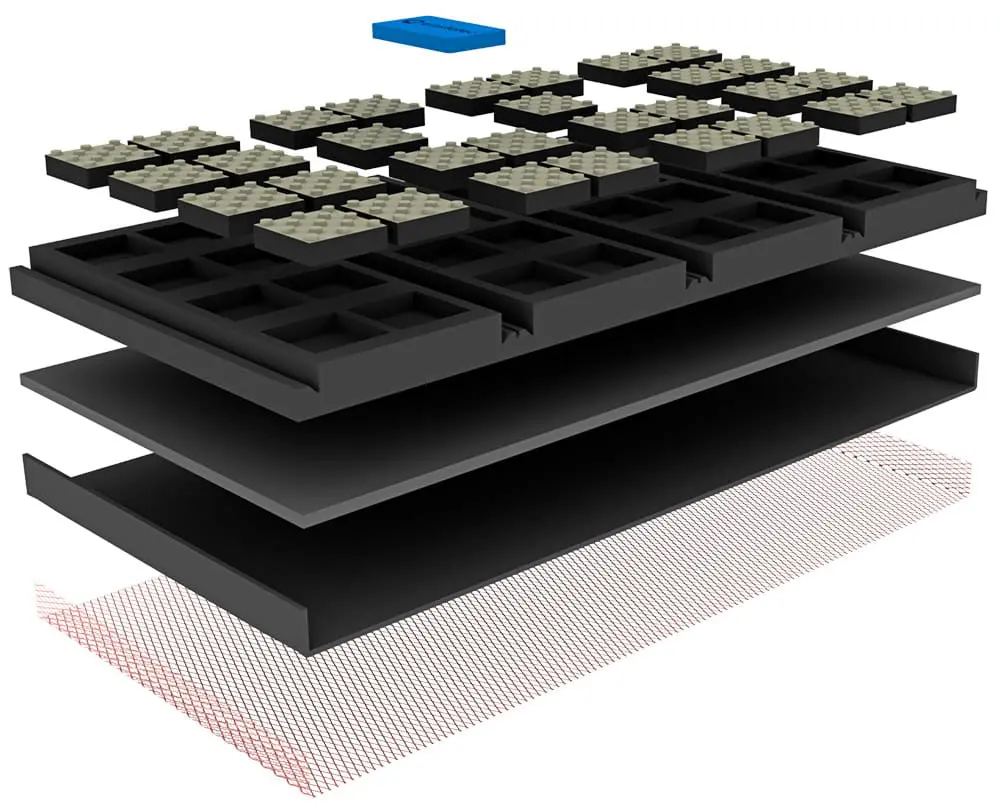

Elastotec Ceramic Lagging consists of vulcanised alumina tiles bonded into rubber.

The rubber is bonded to five surfaces of the tile to ensure tile cushioning and better adhesion strength. Tiles provide high abrasion resistance. Flexible rubber backing containing Elastotec rubber compounds is used to provide abrasion resistance and flexibility to the tile.

Elastotec ceramic pulley lagging is made using two different rubber layers extruded together. The top layer being the high abrasion resistant layer to which the tiles are vulcanised onto and the bottom layer being the adhesion CN bonding layer. Elastotec’s specially formulated neoprene based CN bonding layer is engineered to achieve ultimate adhesion when bonded to steel pulley surfaces. Elastotec’s CN bonding layer has a buffed finish to provide an optimum surface contact area that increases adhesion force.

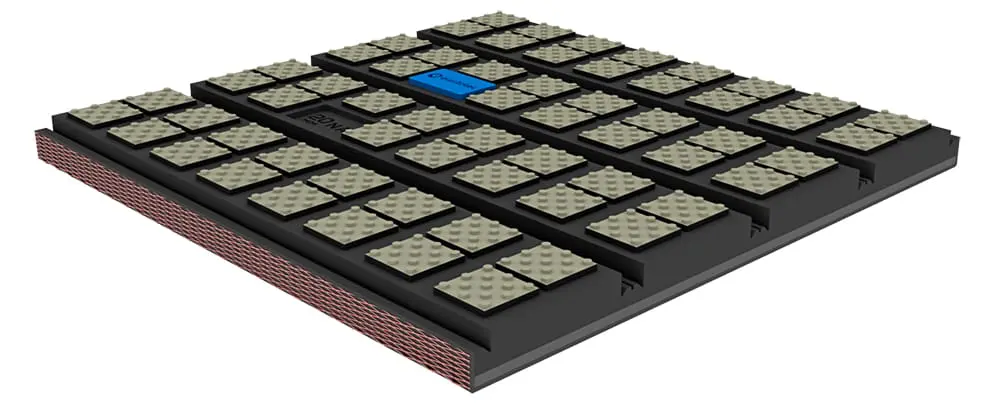

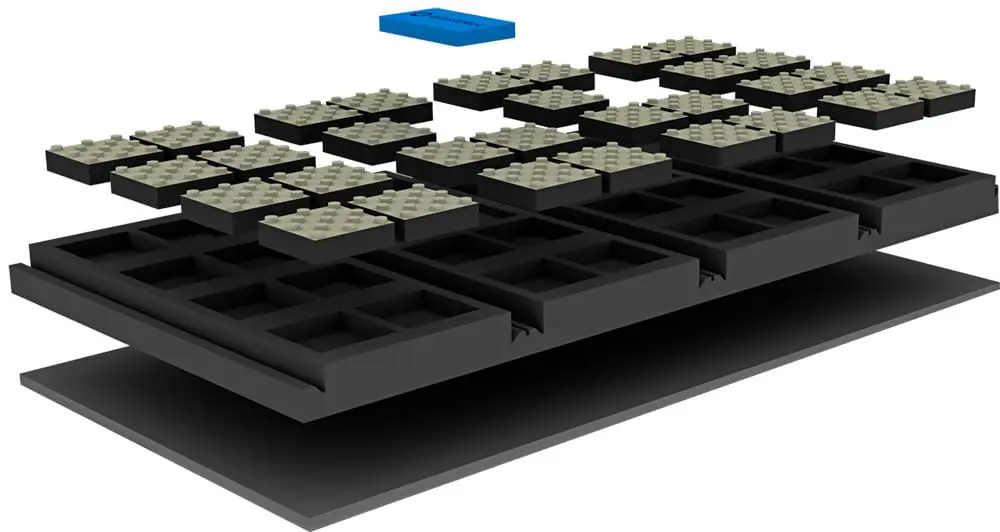

Cold bonded

Coloured logo

High performance Elastotec ceramic tiles

Elastotec 100% rubber tear bonding system

Edge sipe

3 cutting location sipe

CN buffed adhesion layer

Hot Vulcanised

Premium finish

Ceramic proven tile design

Uncured bonding layer

Plastic release liner

Edge Sipe

Coloured Logo

Rubber Specifications

| NAT | FRAS | |

|---|---|---|

| Polymer | SBR | Blend |

| Tensile strength (MPa) min ISO37 | 18.0 | 16.0 |

| % Elongation min ISO37 | 550% | 500% |

| Hardness (shore A) ISO868 | 65+/-5 | 65+/-5 |

| Abrasion resistance max vol. loss ISO 4649 method A (non-rotating) | 70mm3 | 150mm3 |

| FRAS - MDG3608 and MSHA Standards | N/A | PASSED/ACCEPTED |

| Heat ageing (Property change after 70°C 168hs) | Tensile strength +1% Elongation -15% Hardness 5 points | Tensile strength +5% Elongation -1% Hardness 3 points |

| Continuous operating temperature | -40/+70°C | -40/+70°C |

Ceramic Specifications

| Aluminium oxide | 96% |

|---|---|

| Aluminium oxide | 96% |

| Specific gravity g/cm3 | 3.7 |

| Vickers hardness HV (10) | 1000 plus |

| Flexural strength (Mpa) | 300 |

| Compressive strength (Mpa) | 1800 |

| Fracture Toughness (Mpa m1/2) | 3.5 |

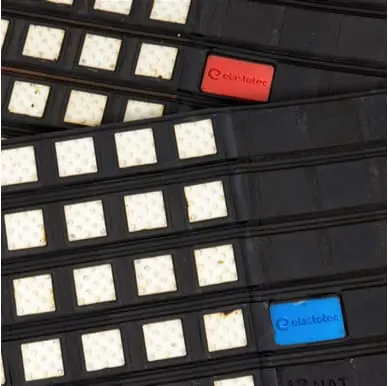

NAT and FRAS

Elastotec Rubber and Ceramic Laggings are available in both SBR (NAT) and FRAS approved compounds. FRAS lagging is MDG3608 certified and MSHA accepted, made of a fire resistant and antistatic compound that is primarily used in applications where there is a risk of fire and/or explosion as a safety precaution. These applications include underground coal mines, power stations, grain handling facilities and sugar terminals. Elastotec uses blue coloured inserts to identify SBR (NAT) rubber products and red coloured inserts to identify FRAS rubber products.

Elastotec lagging can be applied to pulleys by cold bonding or by hot vulcanisation.

ELASTOTEC COLD BONDING

PULLEY LAGGING

Elastotec Cold Bonding Rubber Lagging has the CN buffed bonding layer packed in plastic to protect and keep it fresh and free from contamination until application to the pulley.

A rubber tear bond is achieved by using Elastotec Metal Primer 2205 and Elastotec Cold Bonding Adhesive to chemically interlock with the CN bonding layer, making a strong interface between the layers.

An Elastotec approved applicator using the Elastotec application procedure will achieve reliable adhesion levels that exceed the 9 N/mm industry standard and are typically at 12 N/mm.

ELASTOTEC HOT VULCANISING PULLEY LAGGING

Elastotec Hot Vulcanising Rubber Lagging has a 1.2mm thick uncured rubber layer applied to the back and sides of the lagging.

Hot Vulcanising Lagging is supplied packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until application to the pulley.

Application by a trained Elastotec approved applicator using the Elastotec application procedures will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.

Lagging specifications – Medium Double Row Ceramic 42% Lagging

COLD BONDED - NAT. DIMENSIONS DIMPLE TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-N-12K | 250mm-252mm | 11.5mm-12.5mm | 58.2m | 6.10kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-N-15K | 250mm-252mm | 15mm-16mm | 48.5m | 6.90kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-N-20K | 250mm-252mm | 19mm-20mm | 38.8m | 7.20kg |

COLD BONDED - NAT. DIMENSIONS PLAIN TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-N-12P | 250mm-252mm | 11.5mm-12.5mm | 58.2m | 6.50kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-N-15P | 250mm-252mm | 15mm-16mm | 48.5m | 7.20kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-N-20P | 250mm-252mm | 19mm-20mm | 38.8m | 7.80kg |

COLD BONDED - FRAS. DIMENSIONS DIMPLE TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-F-12K | 250mm-252mm | 11.5mm-12.5mm | 58.2m | 6.40kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-F-15K | 250mm-252mm | 15mm-16mm | 48.5m | 7.10kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-F-20K | 250mm-252mm | 19mm-20mm | 38.8m | 7.70kg |

COLD BONDED - FRAS. DIMENSIONS PLAIN TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-F-12P | 250mm-252mm | 11.5mm-12.5mm | 58.2m | 7.00kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-F-15P | 250mm-252mm | 15mm-16mm | 48.5m | 7.70kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-F-20P | 250mm-252mm | 19mm-20mm | 38.8m | 8.30kg |

Product code for different lengths: Add 5-digit number to indicating length in mm.

Example

Strip: 15mm thick cold bonded, NAT, 1.2m ceramic length product code:

ELA-DRC42-N-15K-01200

Ceramic strips are supplied with 130mm rubber end pieces at each end.

Thickness variation (all strips/pulley) +/-0.5mm.

Ceramic Lagging with thickness >15mm only recommended for pulleys with diameters over 600mm.

Lagging Specifications – Hot Vulcanised 42% Ceramic Lagging

HOT VULCANISED - NAT. DIMENSIONS DIMPLE TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-N-12KV | 250mm-252mm | 12.5mm-13.7mm | 9.7m | 6.60kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-N-15KV | 250mm-252mm | 16mm-17.2mm | 9.7m | 7.40kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-N-20KV | 250mm-252mm | 21mm-22.2mm | 9.7m | 7.70kg |

HOT VULCANISED - NAT. DIMENSIONS PLAIN TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-N-12PV | 251mm-255mm | 13mm-14.2mm | 9.7m | 7.00kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-N-15PV | 251mm-255mm | 16mm-17.2mm | 9.7m | 7.70kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-N-20PV | 251mm-255mm | 21mm-22.2mm | 9.7m | 8.30kg |

HOT VULCANISED - FRAS. DIMENSIONS DIMPLE TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-F-12KV | 250mm-252mm | 12.5mm-13.7mm | 9.7m | 6.90kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-F-15KV | 250mm-252mm | 16mm-17.2mm | 9.7m | 7.60kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-F-20KV | 250mm-252mm | 21mm-22.2mm | 9.7m | 8.30kg |

HOT VULCANISED - FRAS. DIMENSIONS PLAIN TILES

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| 42% Ceramic Lagging 12mm | ELA-DRC42-F-12PV | 251mm-255mm | 13mm-14.2mm | 9.7m | 7.50kg |

| 42% Ceramic Lagging 15mm | ELA-DRC42-F-15PV | 251mm-255mm | 16mm-17.2mm | 9.7m | 8.30kg |

| 42% Ceramic Lagging 20mm | ELA-DRC42-F-20PV | 251mm-255mm | 21mm-22.2mm | 9.7m | 8.80kg |

The 42% Ceramic Lagging is supplied in strips with a central ceramic length to match the belt width and 130mm rubber end pieces at each side.

Storage recommendations:

- Stock usage based on a first-in first-out method (FIFO).

- The storage room for lagging must be cool, dry and dust-free.

- Avoid storage places near sources of ozone generating equipment.

- Do not store outside.

- Avoid storage in direct sunlight and strong artificial light as UV light can damage the products and may lead to a premature ageing.

- Under no circumstances should fuels, lubricants, acids, disinfectants, solvents or other chemicals be stored in the same storage area.

- Keep the storage place clean. Protect the material from dust, water etc. with suitable coverings.

- Allow 24 hours before use when lagging is removed from cold storage.

Shelf life:

COLD BONDING LAGGING AND WEAR PANELS

- Stored <25°C 3 years shelf life

- Light buffing of bonding surfaces is recommended if over 4 months from production date

HOT VULCANISED LAGGING AND WEAR PANELS

- <7°C and away from UV and ozone generating equipment 12 months. Products stored for longer than 6 months will need to be re-tested for adhesion before being used, and the recommended shelf life is 12 months.

ADHESIVES AND PRIMERS

- Store in flammable goods cabinet

- Stored <25°C

- Shelf life:

- Primers 2 years

- Cold bonding adhesive 2 years

- Hot vulcanising adhesive 12 months

- Direct bond adhesive 2 years

Products stored under the above conditions for longer periods of time than recommended need to be re-tested for adhesion before being used. If any doubts on storage recommendations, contact Elastotec.