Description

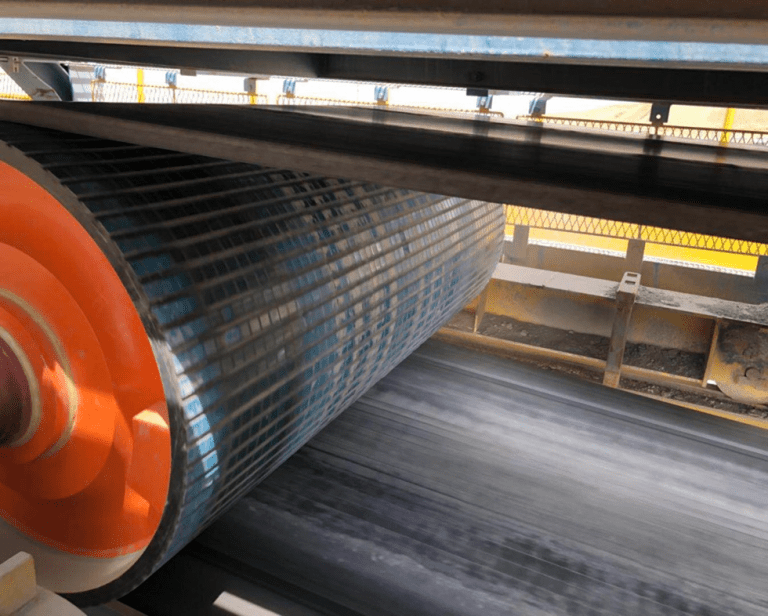

Application

Polyurethane lagging shall be specified on non-drive pulleys when:

- There’s a requirement for higher abrasion resistance than what achieved with rubber laggings.

- In applications where there’s slippage between the conveyor belt and the lagging surface, such as on bend pulleys and non-drive pulleys on turnover conveyors. Its low coefficient of friction make Polyurethane Lagging kind to the belt bottom cover.

- When there’s buildup of material between the belt and the lagging.

Key features and benefits

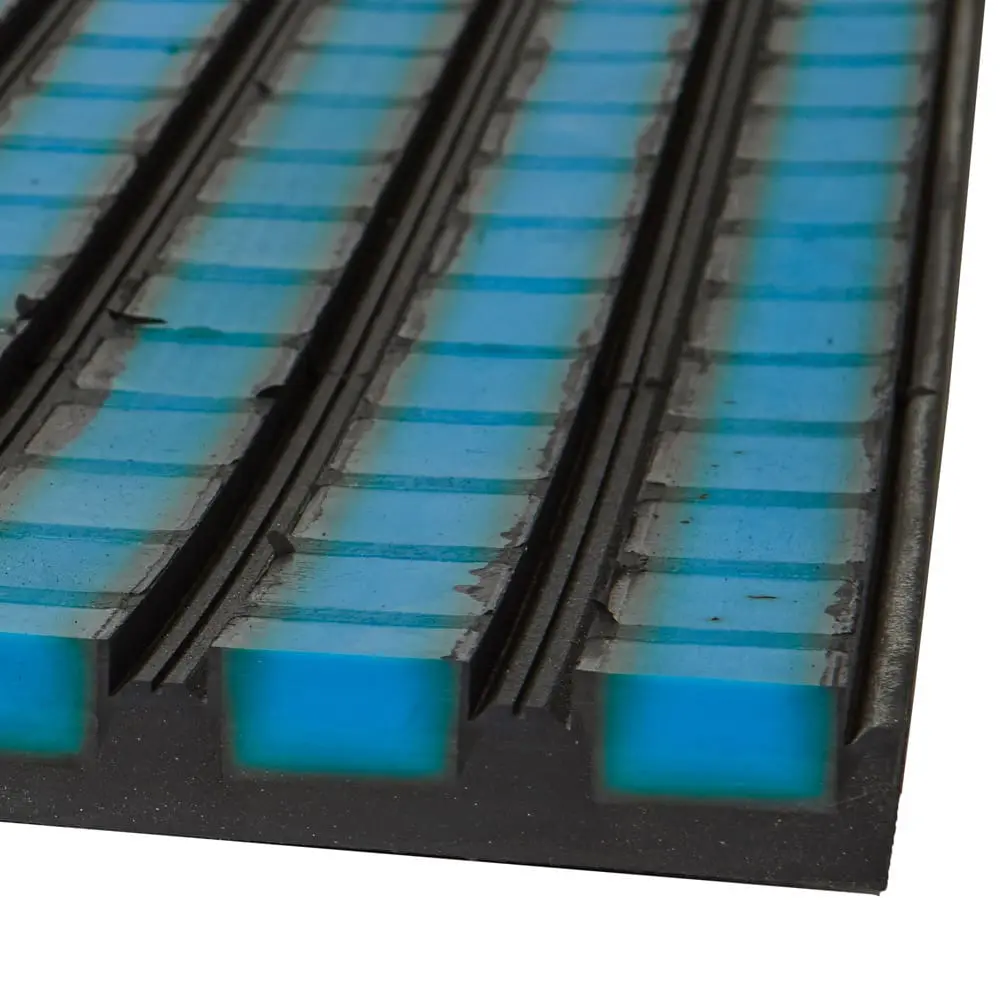

- Highly abrasion resistant polyurethane inserts prevent wear on pulley shell and offers positive dirt release and shedding.

- Precision moulded strip with optimum polyurethane properties.

- Supplied in strip form 250mm wide for easy handling.

- Strips packed in plastic film to preserve buffed bonding layer ready for application.

- Coloured TPU inserts.

- Low coefficient of friction difficult to stick to, resists build up and is kind to belt cover.

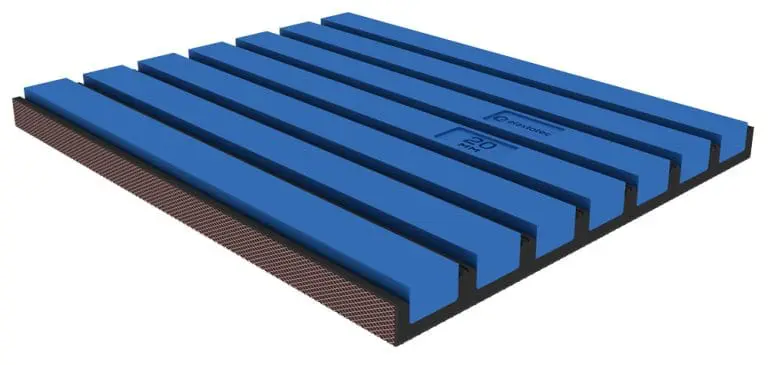

Design

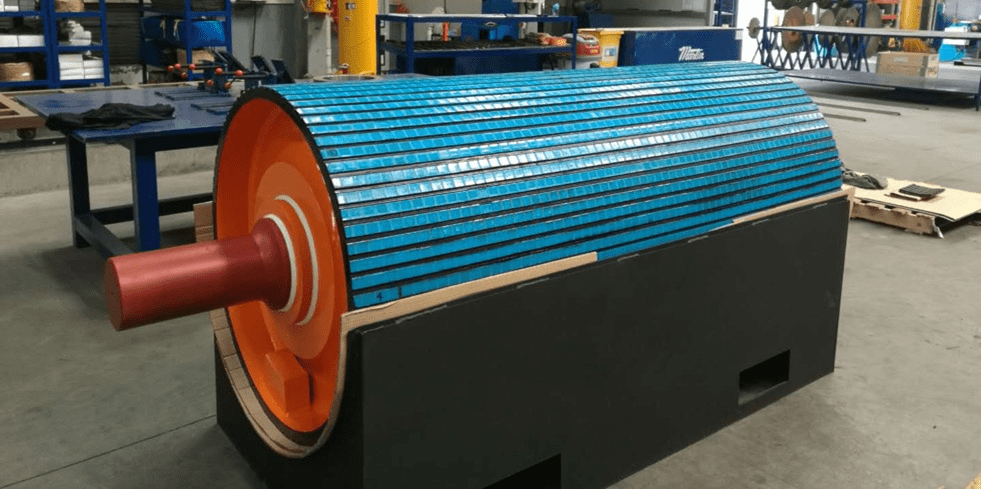

Elastotec Polyurethane Lagging is 250mm wide to ensure easy handling and application. It is supplied in long roll lengths that fit on standard sized pallets to eliminate waste and for cost effective transportation and storage. It can be supplied in thicknesses from 10mm to 20mm.

COLD BONDED

Thickness logo

Elastotec rubber tear bonding system

Edge sipe

3 cutting location sipe

Premium finish CN buffed

adhesion layer

Engineered PU with

low coefficient of friction

and high abrasion resistance

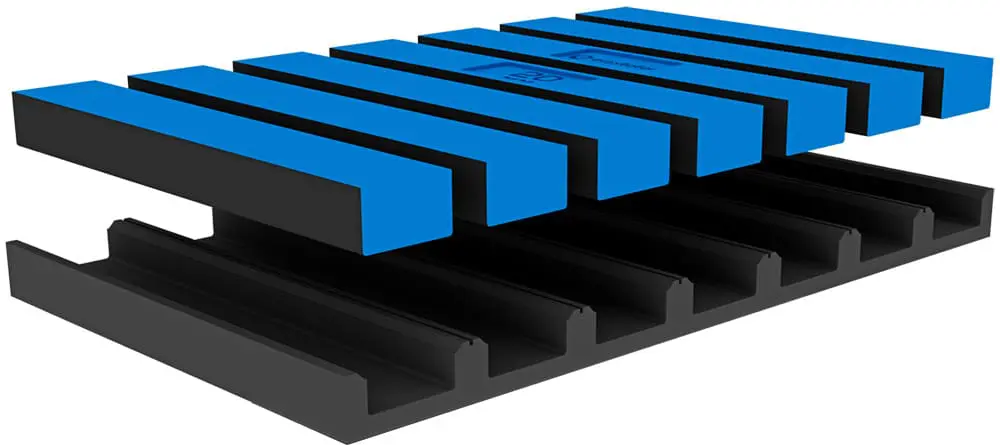

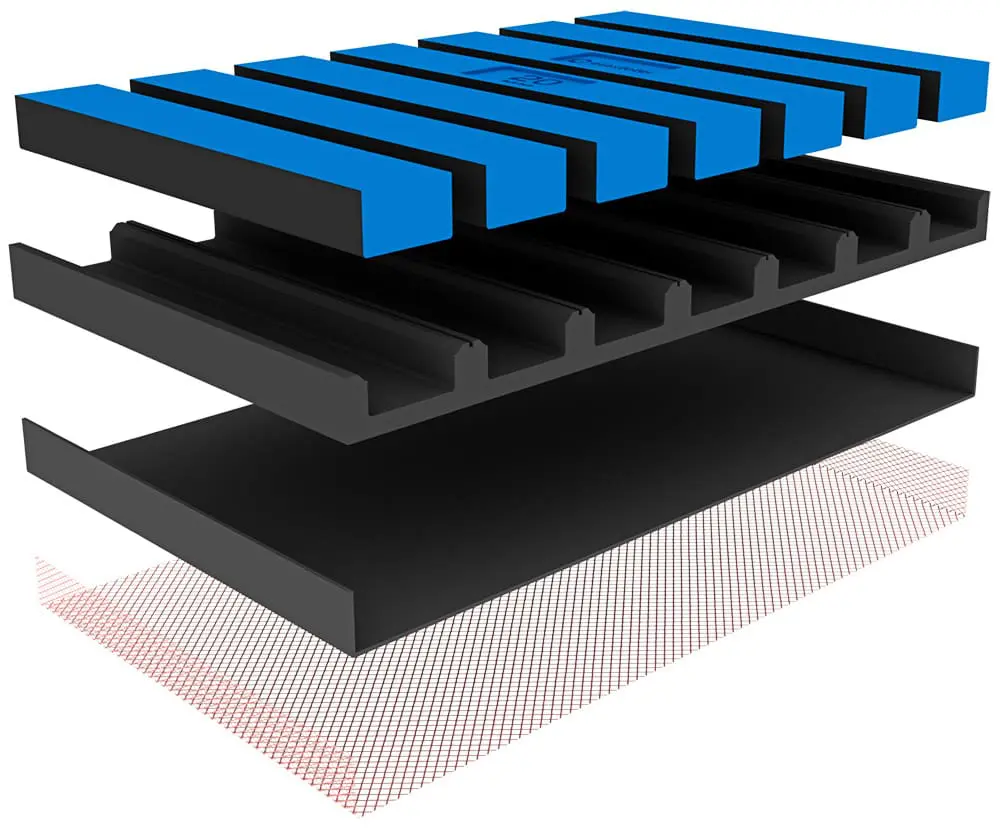

HOT VULCANISED

Thickness logo

Elastotec rubber tear bonding system

Edge sipe

3 cutting location sipe

Plastic release liner

Uncured bonding layer

Premium finish CN buffed

adhesion layer

Engineered PU with

low coefficient of friction

and high abrasion resistance

Polyurethane Specifications

| Hardness (shore A) | 85+/-5 | ASTM D2240 |

| Tensile strength | 40 Mpa | DIN53504 |

| Elongation at break | 500% | ASTM D412 |

| Abrasion loss (volume loss) | 25mm3 | DIN 53516 – non rotating - method A |

Elastotec lagging can be applied to pulleys by cold bonding or by hot vulcanisation.

ELASTOTEC COLD BONDING

PULLEY LAGGING

Elastotec Cold Bonding Rubber Lagging has the CN buffed bonding layer packed in plastic to protect and keep it fresh and free from contamination until application to the pulley.

A rubber tear bond is achieved by using Elastotec Metal Primer 2205 and Elastotec Cold Bonding Adhesive to chemically interlock with the CN bonding layer, making a strong interface between the layers.

An Elastotec approved applicator using the Elastotec application procedure will achieve reliable adhesion levels that exceed the 9 N/mm industry standard and are typically at 12 N/mm.

ELASTOTEC HOT VULCANISING PULLEY LAGGING

Elastotec Hot Vulcanising Rubber Lagging has a 1.2mm thick uncured rubber layer applied to the back and sides of the lagging.

Hot Vulcanising Lagging is supplied packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until application to the pulley.

Application by a trained Elastotec approved applicator using the Elastotec application procedures will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.

Lagging Specifications – Polyurethane Lagging

COLD BONDED

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| Polyurethane Lagging 12mm | ELA-PU-PLN-N-12 | 249mm-251mm | 11mm-12mm | 58.2m | 3.70kg |

| Polyurethane Lagging 20mm | ELA-PU-PLN-N-20 | 249mm-251mm | 19mm-20mm | 35.0m | 6.39kg |

Product code for different lengths: Add 5-digit number indicating length in mm.

Example: 12mm 58.2m roll product code: ELA-PU-PLN-N-12-58200

20mm 1.2m strip product code: ELA-PU-PLN-N-20-01200

For strips always allow 100mm extra length over the pulley face width to have 50mm at each end of overhang.

HOT VULCANISED

| PRODUCT | CODE | WIDTH | THICKNESS | LENGTH | WEIGHT/lm |

|---|---|---|---|---|---|

| Polyurethane Lagging 12mm | ELA-PU-PLN-N-12V | 249mm-251mm | 12.2mm-13.2mm | 9.7m | 4.21kg |

| Polyurethane Lagging 20mm | ELA-PU-PLN-N-20V | 249mm-251mm | 20.2mm-21.2mm | 9.7m | 6.90kg |

Product code for different lengths: Add 5 digit number indicating length in mm.

Example: 12mm 9.7m roll product code: ELA-PU-PLN-N-12V-09700

20mm 1.2m strip product code: ELA-PU-PLN-N-20V-01200

For strips always allow 100mm extra length over the pulley face width to have 50mm at each end of overhang.

Thickness variation (all strips/pulley) +/-0.5mm

Polyurethane lagging with thickness >15mm only recommended for pulleys with diameters over 400mm.

Storage recommendations:

- Stock usage based on a first-in first-out method (FIFO).

- The storage room for lagging must be cool, dry and dust-free.

- Avoid storage places near sources of ozone generating equipment.

- Do not store outside.

- Avoid storage in direct sunlight and strong artificial light as UV light can damage the products and may lead to a premature ageing.

- Under no circumstances should fuels, lubricants, acids, disinfectants, solvents or other chemicals be stored in the same storage area.

- Keep the storage place clean. Protect the material from dust, water etc. with suitable coverings.

- Allow 24 hours before use when lagging is removed from cold storage.

Shelf life:

COLD BONDING LAGGING AND WEAR PANELS

- Stored <25°C 3 years shelf life

- Light buffing of bonding surfaces is recommended if over 4 months from production date

HOT VULCANISED LAGGING AND WEAR PANELS

- <7°C and away from UV and ozone generating equipment 12 months. Products stored for longer than 6 months will need to be re-tested for adhesion before being used, and the recommended shelf life is 12 months.

ADHESIVES AND PRIMERS

- Store in flammable goods cabinet

- Stored <25°C

- Shelf life:

- Primers 2 years

- Cold bonding adhesive 2 years

- Hot vulcanising adhesive 12 months

- Direct bond adhesive 2 years

Products stored under the above conditions for longer periods of time than recommended need to be re-tested for adhesion before being used. If any doubts on storage recommendations, contact Elastotec.