T&T Perú 2023

Thank you to the Peruvian mining sector. Thank you for the space to discuss your challenges. Thank you for the opportunity to redefine conveyor reliability together. So much to work together on. So much to learn together.

Thank you to the Peruvian mining sector. Thank you for the space to discuss your challenges. Thank you for the opportunity to redefine conveyor reliability together. So much to work together on. So much to learn together.

Experts from Elastotec and the University of Newcastle explain the why it is vital to understand the coefficient of friction between the pulley lagging and the belt for optimising the design, performance, efficiency, and safety of conveyor systems.

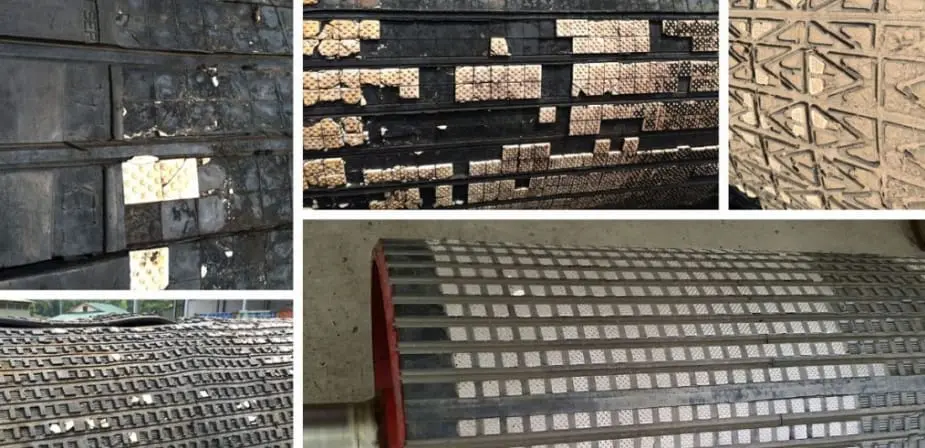

The Elastotec aim is no pulley failures due to inadequate pulley lagging. Compare the difference between cold bonded and hot vulcanised lagging to see that hot vulcanised lagging is A GOOD BUSINESS DECISION.

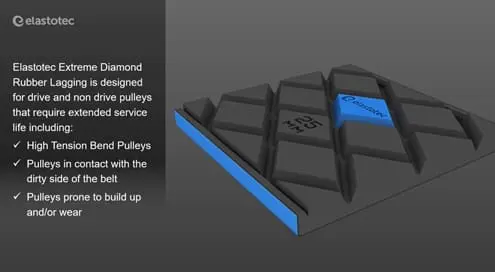

Elastotec extreme diamond rubber lagging is designed for drive and non drive pulleys that require extended service life.

Ceramic lagging is chosen for pulleys where a long trouble free service life is required to ensure that the conveyor is operational when required and