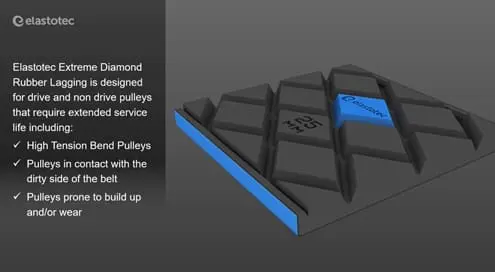

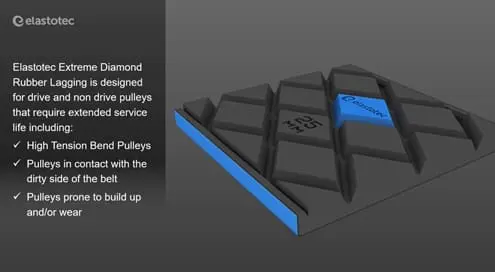

Elastotec Extreme Rubber Lagging

Elastotec extreme diamond rubber lagging is designed for drive and non drive pulleys that require extended service life.

Elastotec extreme diamond rubber lagging is designed for drive and non drive pulleys that require extended service life.

At Elastotec, we engineer lagging solutions that keep conveyors running. Here are some causes of lagging failure.

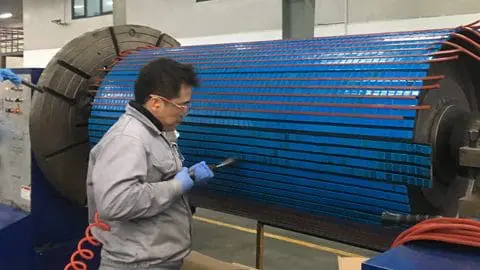

In November 2017 a major iron ore port facility in the Pilbara decided to replace the ceramic lagging on a high tension bend pulley – the ceramic lagging had suffered physical damage on one edge that had exposed the pulley shell. With a capacity of around 180 million tonnes/annum of iron ore the port operates 24/7 year round and so reliability of the conveyor system is critical to achieving the maximum ore through put.

Oyu Tolgoi is a large copper mine that has both open-cut and underground operations and has been operating since 2013. The mine is jointly owned by the Mongolian government and Rio Tinto and is located in the South Gobi Desert. Once fully operational, the mine is expected to produce 450,000 tonnes of copper annually.

Mining is an industry where reliability is crucial and unplanned down time can result in millions of dollars lost over a single day. Pulleys are

Vale-operated Vargem Grande mine site is located in the state of Minas Gerais, Brazil and contains 2.53 billion tonnes of proven and probable iron ore reserves, making it the world’s fourth biggest iron ore mining operation. The Vargem Grande site comprises three open-pits: Tamandua, Capitao do Mato and Aboboras.