Wear panel solutions engineered for improved transfer chute performance

You need a wear panel solution that’s quick and easy to install

You want a system that enhances the service life of your chutes

And it needs to reduce the safety risks for your operators

Elastotec provides global mining operations with wear panel solutions that reduce down-time, maximises output production and manages OH&S risks.

Wear Panel Installations

Reduce

shut down time

Increase conveyor operation and production output

Achieve more with the same amount of labour

Improve

OH&S outcomes

Introducing Magnefast Wear Panels

-

Chutes

-

Launders

-

Underpans

-

Vibratory feeders

-

Apron feeders

-

Mobile surge loaders

-

Deflectors

-

Diverter valves

-

Stacker/reclaimers

Improve the performance of your transfer chutes with the Magnefast wear liner system.

Up to 80% less shut down time

UP TO 60% LESS LABOUR COST

Up to 60% less OH&S risk

100% LESS HYDRAULIC, pneumatic & ELECTRIC TOOLS

Wear Panel Systems

Every mine site, every ore body presents unique challenges when it comes to the service life and wear of equipment. Elastotec’s engineered wear panel solutions add value to your operation by reducing or eliminating your production challenges.

Direct Bond Wear Panels

Made with a high-performance ceramic and proven epoxy adhesive for ease of installation and increased service life.

Suitable for

- Chutes

- Cyclones

- Launders

- Pipes & Tanks

- Screen beam underpans

- Vibratory feeders

Hot Vulcanised Wear Panels

This pioneered solution provides consistent 100% rubber tear bond to the chute wall ensuring the longest possible service life.

Suitable for

- Chutes

- Cyclones

- Launders

- Pipes & Tanks

- Conveyor transfer points

- Screen beam, underpans & components

- Vibratory feeders

- Hoses

Cold Bonded Wear Panels

Ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.

Suitable for

- Chutes

- Cyclones

- Launders

- Pipes & Tanks

- Screen beam, underpans & components

- Vibratory feeders

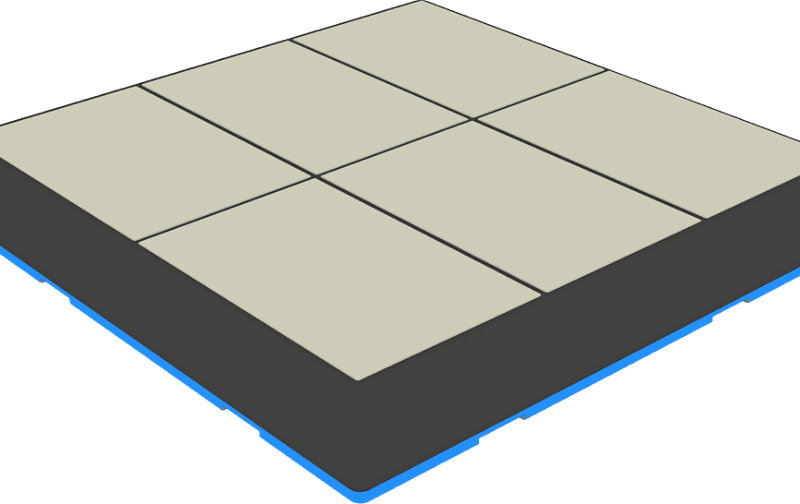

Magnefast Wear Panels

A unique, single sided high performance magnetic attachment system that provides benchmark performance for liner changeout time and OH & S risk.

Suitable for

- Chutes

- Cyclones

- Launders

- Pipes & Tanks

- Screen beam underpans

- Vibratory feeders

Want to know about wear panel solutions?

Speak with one of our experienced consultants today

Why use Elastotec’s wear panel solutions?

Wear panel problems that can be eliminated to improve chute performance:

- Ceramic tile loss due to debonding

- Debonding of the wear panel from the chute surface

- Debonding of ceramic tiles from the panel backing plates

- Corrosion and seizing of mounting studs

- Corrosion of wear panel backing plates

- Gaps between studded wear panels

Wear panel features that can improve performance, make liner changes easier and reduce OH&S risks

- Single sided attachment – easy to use and install

- No stud alignment necessary, so no gaps between panels

- No need to chisel direct bond liners out of chutes for replacement

- Reduced weight

- No working at heights risk outside the chute – no scaffolding, no drop risk

Read how Elastotec’s wear panel solutions are helping mining companies improve their operations

Colliery Transfer Chute Diverter

Elastotec Magnefast Ceramic Wear Panels were chosen for the application in this colliery transfer chute as the use of studded wear panels would have been very difficult and time co

Magnefast Bulk Port Authority

This port facility is one of the largest in the world and handles shipments of iron ore, lithium concentrate and salt. In October 2019 a trial installation of the Elastotec Magnefa

Introduction to Magnefast

Magnefast is a patented single sided attachment system for wear panels that uses high strength neodymium magnets to hold the panels in place.

Quarry – Screen Underpan Chute

This quarry located in the south-eastern region of New South Wales is a hard rock quarry that can produce up to 1.5 million tonnes per annum of quarry products.

contact us

Speak to an expert

from Elastotec

If you’d like to know more about how Elastotec’s wear panel solutions can reduce your downtime, speak with one of our experienced engineers.